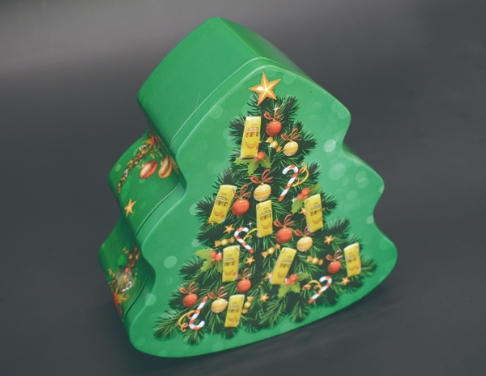

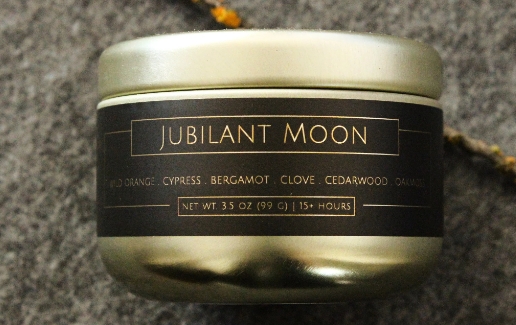

Personalized mint tins in many different designs

Personalized mint tins are great for packaging promotional giveaways, holiday gifts, and more, as well as for storing mints. Because they are compact, practical, and customizable, they are the ideal packaging solution for adding a personal touch to any event or brand. This blog post takes a deep dive into the different design options for personalized mint tins and offers tips on making a lasting impression with these versatile items.

Customized Shapes and Sizes for Personalized Mint tins

The most intuitive way to distinguish a personalized mint tin is in various shapes and sizes. Personalized mint tins come in various shapes besides the traditional rectangular and round shapes. Heart-shaped jars are popular for romantic events, and of course, there are themed shapes, such as cars, animals, and more, that can enhance the theme of an event or promotion. Designing shapes based on different themes can make your mint tins stand out. Their sizes vary depending on the purpose and the number of products to be filled. Smaller jars are suitable for mints or small candies, perfect as party favors or giveaways. More giant jars can hold other items such as mini chocolates, small gifts, etc.

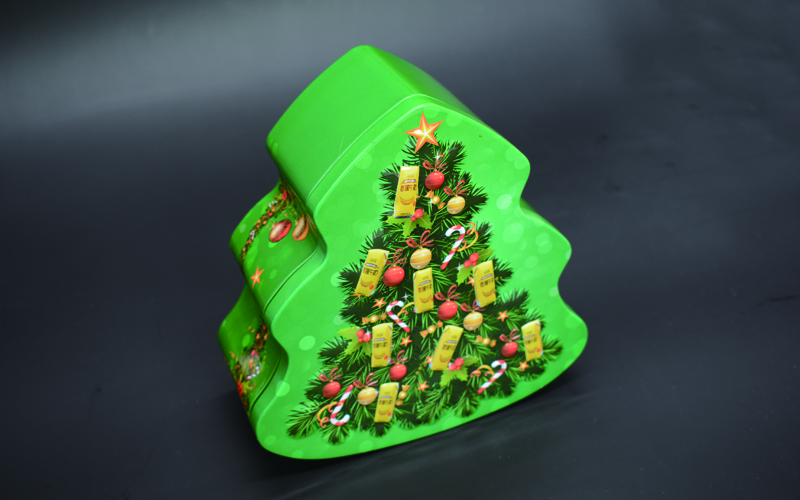

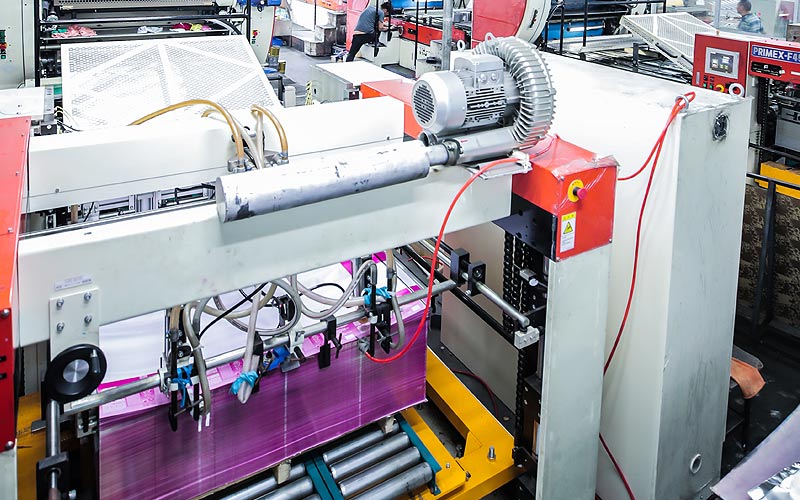

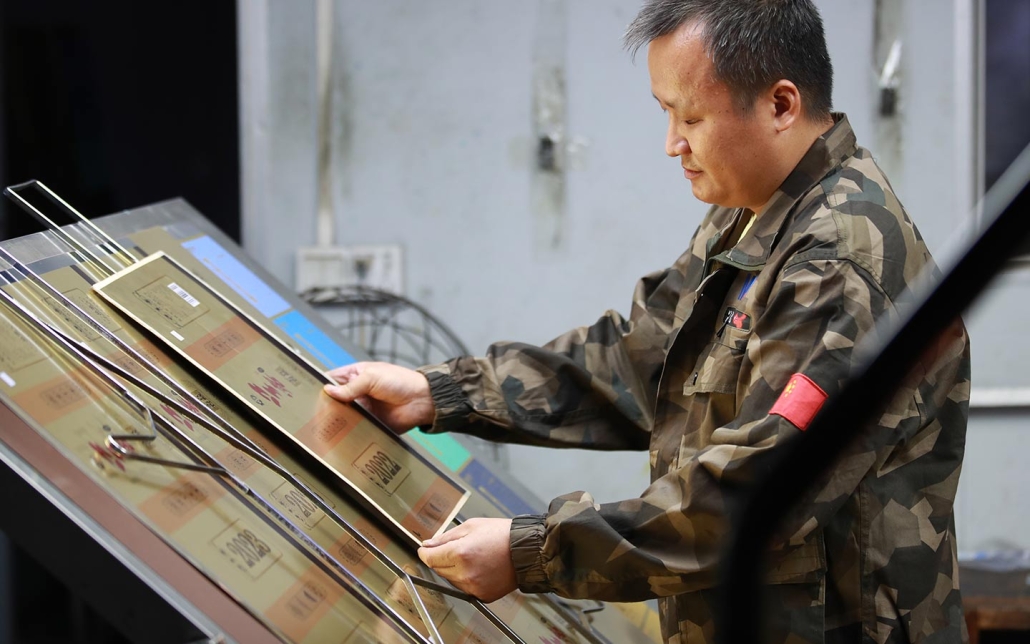

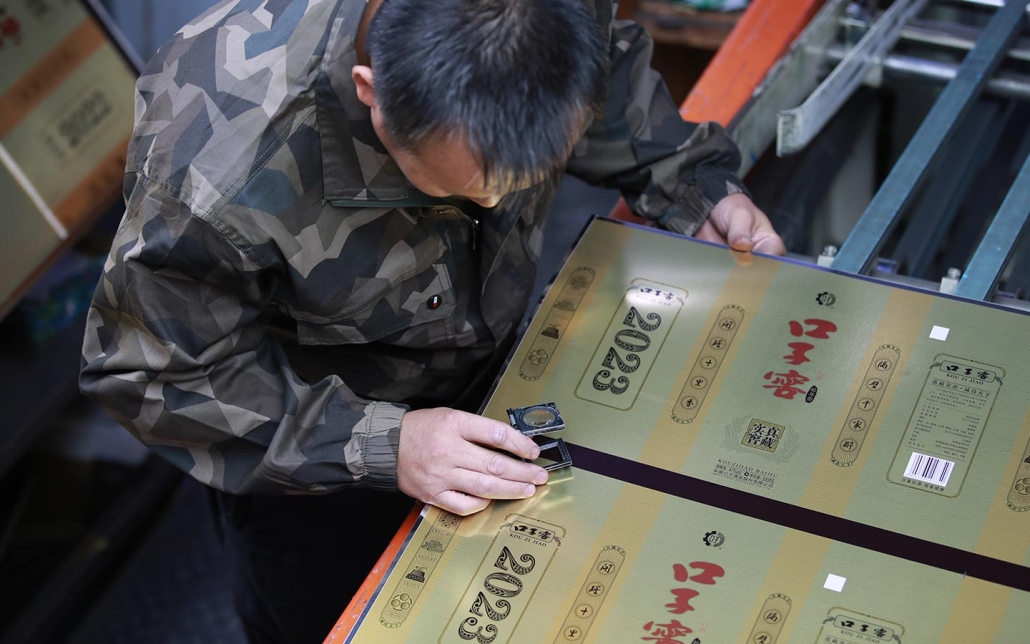

Creative Print Designs

The customization possibilities of personalized mint tins extend to the print design options, allowing for a high degree of personalization and creativity. Full-colour printing includes brand logos, personalized images, and more. This printing method is ideal for businesses that want to highlight their brands. High-quality printing ensures that the design is clear, durable, and not easy to fade, and it can maintain its appeal for a long time. In addition to full-color printing, you can use engraving and embossing to achieve a more refined and tactile effect. Various embossing will present a raised surface, adding a sense of texture and enhancing the visual of the can. In addition, a more economical way is to use labels or stickers instead of printing embossing and other designs. This method’s benefit is that you can easily update the design, making it ideal for seasonal events.

More environmentally friendly design

As consumers’ environmental awareness continues to increase, as a tin can manufacturer, we will also add environmental sustainability to the production design of personalized mint tins. One aspect of this is to use environmentally friendly and highly reusable tinplate materials to make personalized mint tins. This recyclable metal can reduce the impact on the environment. Moreover, the cans made from them are also very durable, can be reused, and cannot easily deform. Encourage users to refill the cans with different items to enhance the continuous use value of the product.

Personalized Mint Tins for Brand Marketing

More brand-related designs can be added to personalized mint tins for users who want better marketing and promotion. RetailRetail products can be customized with the brand’s iconic design, logo, and color. Retailers can offer these tins as standalone products or as a gift set. In addition, a batch of related theme cans can be designed according to different holiday events, and traffic related to holiday themes can be used to attract consumers to buy and increase sales. This kind of limited gift is often more prevalent. In addition, we can see various collaborations between different brands at the moment, so we can also create joint personalized mint tins. These collaborations can promote brands to new audiences and create topics for products.

Different opening methods

Personalized mint tin lid designs vary based on the intended use. Here are a few common lid types for opening personalized mint jars, each with its specific features and benefits:

1. Hinged lids:

This is one of the most popular lid designs for mint tins. They are attached to the jar via a hinge, and the lid remains attached to the base when opened. This design is convenient and reduces the risk of losing the lid. Extending this approach is the snap-on hinge. This hinge includes a small pull ring or clasp that snaps into place when the lid is closed, providing a secure seal and preventing accidental opening.

2. Slide-top tins:

This lid slides open and closed along a groove on the side of the tin. It can also be designed with a single slide mechanism that allows the lid to slide open in one direction. There are also dual slide mechanisms that allow the lid to slide in both directions, providing additional flexibility and convenience.

3. Screw-top lids:

Standard screw-top lids twist on and off, similar to tins. This design ensures a tight seal but may be less convenient for frequent use.

Unlimited possibilities through different designs

Personalized mint tins offer unlimited design possibilities through shapes, sizes, printed designs, opening methods, etc., making them suitable for various occasions and uses. With various design options and applications, different users and consumers can make the most of personalized mint tins.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin