How do custom tin cans handle different types of contents?

Among tin packaging solutions, custom tin cans offer versatility and protection for a wide range of products. From food to cosmetics and industrial materials, custom tin cans can be designed to meet the specific needs of various contents while enhancing product display and extending shelf life. This blog post will explore how custom tin cans can handle different types of content, providing valuable insights for manufacturers, retailers, and consumers across multiple industries.

Custom Tin Cans for the Food Industry

Custom tin cans are a popular choice for packaging food because of their excellent protective properties. These cans block moisture, light, and air, helping preserve the contents’ freshness and flavour. Their construction typically includes a layer of tin-coated steel coated to resist corrosion and maintain structural integrity under various conditions. This helps prevent leaks and contamination, which is critical to protecting food. In addition, you can equip custom tin cans with specialized linings or coatings to prevent further chemical reactions, ensuring that food stays uncontaminated and fresh. Besides their protective functions, you can design them with features that enhance usability and safety. Meanwhile, you can customize the exterior of the can with high-quality printing, embossing, and other decorative elements to help the product stand out on store shelves.

Custom Tin Cans: Protecting Cosmetics and Personal Care Products

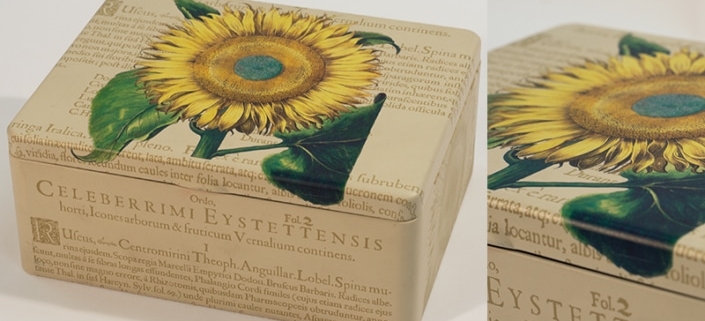

Custom tin cans for storage packaging of creams, lip balms, powders, and other sensitive items provide a secure, airtight seal that prevents contamination and preserves the integrity of the contents. In addition to providing protective properties, you can customize custom tin cans with eye-catching designs, embossed logos, and high-quality finishes to enhance the product’s visual appeal, making them suitable for high-end and luxury brands.

Using custom tin cans in this industry is not just about looks; it also ensures the durability and longevity of the product. Tin cans are solid and durable, providing excellent protection against external factors such as humidity, light, and temperature changes that would otherwise degrade the quality of cosmetics and personal care items. In addition, you can equip custom tin cans with various functional features to enhance the user experience. For example, incorporate easy-open lids, safety closures, and mirror inserts for convenience and functionality. These features protect the product and enhance the brand experience, providing consumers with practical and beautiful packaging.

Handling Special Items

Custom tins offer flexibility and customization options for special items requiring unique packaging solutions. Whether you’re creating a collectable, promotional, or limited edition product, you can design custom tins to fit specific needs and enhance the presentation of the content. You can customize these tins in shape, size, and printing and improve product appeal through innovative design and branding. Additionally, you can design custom tins with specific features, such as unique finishes and special closures, to enhance the overall appearance and functionality of the packaging. Whether for a high-end luxury product or a niche product with specific market appeal, you can design custom tins to meet precise specifications.

Add Brand Identity Customization

By offering you a wide range of customization options, we can create packaging that protects your product and becomes an extension of your brand. Using the latest printing presses manufactured in Japan, Tsing can include detailed branding elements such as logos, slogans, and product information, ensuring that the packaging effectively communicates the brand message.

In addition, matching the tin’s design to the brand’s overall aesthetic, whether through colour scheme, finish, or texture, ensures that consumers receive a coherent and memorable experience. For high-end and luxury brands, this level of customization can enhance the product’s perceived value, making the packaging an integral part of the purchasing decision. Of course, these custom tins can be designed for seasonal promotions, limited editions, or special events, providing a versatile solution that aligns with dynamic marketing strategies.

Solving practical problems for various contents for you

When choosing custom tin cans for different types of contents, solving practical problems is essential to ensure functionality and effectiveness. The unique requirements of each product dictate the need to carefully evaluate several critical factors, including the size of the can, the type of closure, and the lining.

For example, the tin size can be tailored to accommodate the volume of the contents and optimize storage, display, and handling. If it is too large, it will lead to unnecessary space consumption, while a tin can that is too small may affect the accessibility and appearance of the product. In addition, the closure type is another important aspect that must be selected based on the product’s nature and the consumer’s convenience. Screw caps, snap caps, and even hinged caps all provide different levels of security and ease of use.

In addition, the lining of the can is also a key component, especially for products that are sensitive to environmental factors or prone to chemical reactions. Their practicality also extends to stackability, portability, and even sustainability. Stackable designs can improve storage efficiency, while portable and lightweight cans are more attractive to busy consumers.

Maximize your customization capabilities.

The different content treatments mentioned in this article will enable you to decide to enhance product protection, display, and sustainability. Whether you are in the food industry or cosmetics industry or deal with unique items, custom tin cans can provide reliable and customizable packaging options to meet various needs.

-800x423.jpg)

.jpg)

.jpg)

.jpg)

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin