Make your custom tin boxes stand out!

Custom tin boxes are practical, an extension of your brand, and essential to product display and sales. Whether you are using it to package high-end cosmetics, gourmet food, or daily necessities, the design and quality of the tin box will affect the customer’s purchasing behavior. So, in this article, we will tell you how we can make your custom tin boxes stand out in the fiercely competitive market.

The Art of Custom Tin Boxes

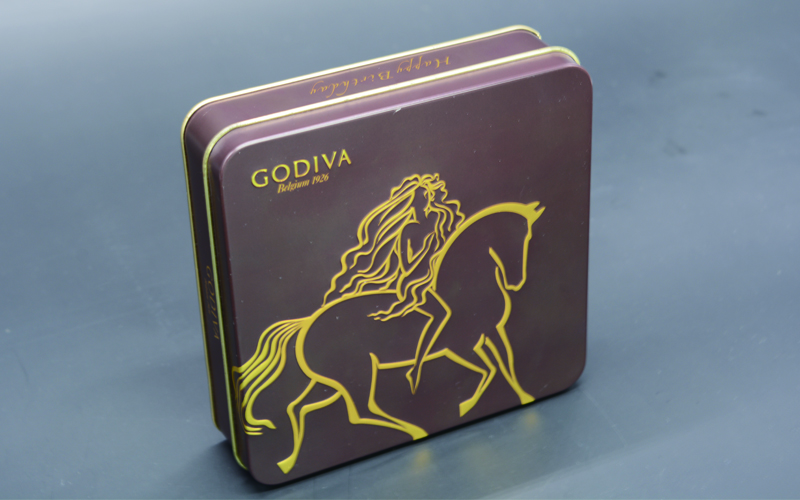

The design of the custom tin boxes is the first thing customers notice, so it needs to leave a deep impression. Therefore, we will add brand elements related to you to the personalized tin box, combine the corresponding design to reflect your brand image, and turn a simple jar into a stunning work of art. Different colors, complex patterns, or unique illustrations will make customers’ eyes light up when they open it. Utilize the entire surface of the jar, including the lid, sides, and bottom, to create a cohesive and attractive design that attracts people from all angles.

Innovative shape and structure

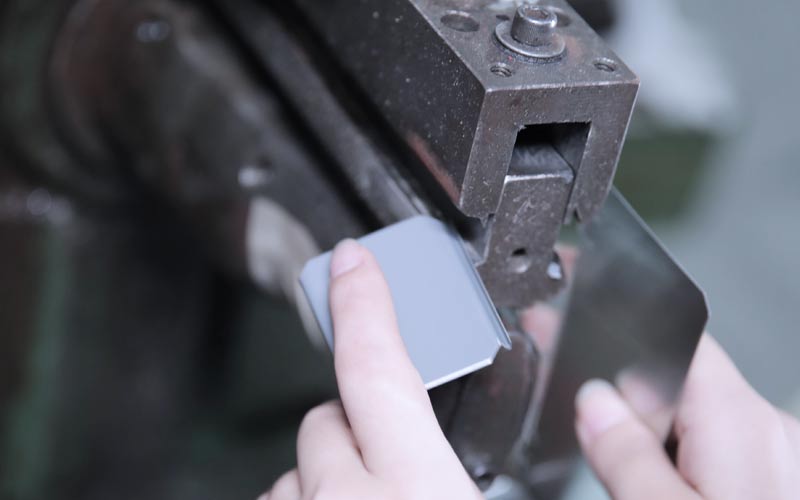

Traditionally, tin boxes are manufactured in standard rectangular or cylindrical shapes. However, they can be customized to any shape you can imagine. You can try unusual shapes that match your product or brand theme, such as a guitar-shaped jar for guitar storage or a heart-shaped box for Valentine’s Day chocolates. Various structural shapes can attract attention on the shelf, become a keepsake that consumers keep, and give your brand long-term exposure. The structure may also include multiple functional elements to enhance usability and aesthetics. For example, adding a sliding lid, hinged lid, or clasp to a tin can secure the contents and add a tactile touch to the packaging.

Features that add value

We don’t just design for appearance, we also don’t neglect functionality. Adding stackability, sealable lids, or dividers can enhance the user experience and increase product sales. From long-term storage boxes to repurposed decorative storage containers, we’ll ensure your designs are beautiful and functional, encouraging consumers to use them in their homes for a long time and continuing to grow your brand’s visibility.

Enhance the finish of the tin box

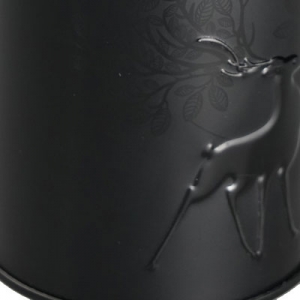

Their texture and feel are also key to standing out, and we can add a variety of surface textures to enhance the user experience and add a unique personality to the product. Common texture finishes include matte, gloss, satin, and metallic. Beyond simple finishes, embossing and debossing techniques can add physical depth and dimension to a design. Embossing can create raised patterns or images on the surface, and these techniques can not only enhance visual appeal but also increase tactile interaction for users.

Quality and sustainability

We use tinplate as the main material for custom iron boxes, a thin steel plate coated with a thin layer of tin. This coating gives the steel excellent corrosion resistance, preventing rust and ensuring the box retains its structural integrity and appearance over time. The material also withstands high-impact environments and resists moisture, protecting the contents from external elements. Regarding sustainability, tinplate scores high for its recyclability, and its durability also contributes to sustainability. They can be reused multiple times for a variety of purposes, from storage containers to decorative items, and have a long life cycle which reduces waste.

Make your tin box stand out

Personalized tin box can leave a unique and lasting impression on your customers. We will add unique features through shape and structure and enhance the appearance of the can, making it stand out on the shelf and strengthening consumer perception of your brand.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin