What are the options for decorative finishes on custom tin cans?

Custom tin cans are a packaging solution chosen by many businesses, as they can be customized to the specific needs of different industries. It is important to have functionality and visual appeal in a tin packaging solution, so adding decorative finishes to custom tins can make them stand out on store shelves and leave a more lasting impression on consumers. This guide will share the various decorative finish options on custom tin cans.

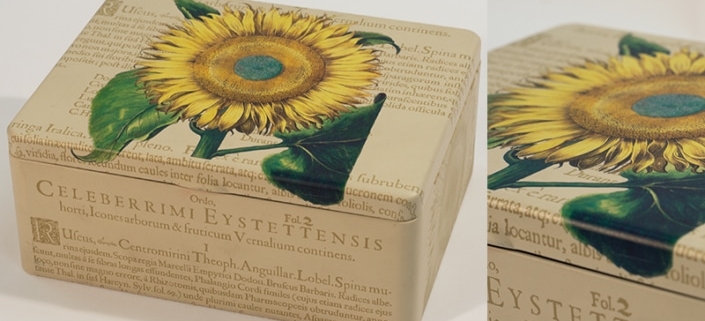

Lithographic Printing on Custom Tin Cans

One of the widely used decorative finishes on custom tins is lithographic printing. A series of plates and inks transfer the image to the tinplate surface throughout printing. Lithographic printing can be used to achieve a variety of effects, such as gradients and shadows. Moreover, lithographic printing is a cost-effective option for high-volume production and is popular for industries such as food and beverage, cosmetics, and promotional products. Another advantage of lithographic printing on custom tins is its durability. This process uses specially formulated inks that meet relevant safety standards and adhere to the tinplate surface. This ensures the printed design remains vibrant and does not fade over time. This becomes especially important for products exposed to harsh environmental conditions or requiring a long shelf life.

3D Embossing on Custom Tin Cans

3D embossing is a decorative finish that adds a tactile dimension to custom tin cans, enhancing their visual appeal and feel. Creating raised designs on the surface of the tin can highlight specific design elements, such as logos, decorative patterns, and branding patterns, making custom tin cans more attractive to consumers. 3D embossing involves pressing a custom die into the tinplate during the creation process to form the desired design. You can apply this process to various areas of the tin can, including the lid, body, or base, allowing for endless creative possibilities.

Different brands can choose specific elements of the 3D embossing or create an overall texture, adding depth and dimension to the packaging. One of their main advantages is its added value to the packaging. The tactile feel of these finishes creates an upscale feel that can enhance the product’s perceived value.

Spot glazing and matte finishes

These two finishes allow brands to create visually striking contrasts and textures. Spot glazing involves applying a gloss or matte varnish to specific areas of the custom tin can, highlighting certain design elements while leaving the rest of the surface untreated. This technique can draw attention to a logo, product name or other important details, creating a dynamic and eye-catching effect.

Spot varnishing is highly customizable, and brands can experiment with different gloss and matte combinations to achieve the desired look. For example, a brand could apply a high-gloss varnish to the logo while leaving the background matte, creating a contrast that makes the logo stand out. Matte finishes create a smooth, non-reflective surface that adds a sense of sophistication to packaging. In addition to their aesthetics, both finishes have practical benefits, helping to protect printed graphics from scratches, smudges and other forms of wear and tear.

Special coatings and textures

Special coatings and textures can add a unique tactile element to packaging. Applying special coatings, such as soft touch and rubberized or textured coatings, to the surface of custom tins creates a unique feel and look. This finish is ideal for products that want to stand out on store shelves and create a memorable consumer experience, such as high-end cosmetics, luxury food or promotional products. The tactile properties of these finishes can engage consumers on a deeper level and increase the likelihood of repeat purchases. Combining it with other decorative techniques, such as embossing, debossing, or lithography, creates a multi-dimensional effect, adding depth and complexity to the design.

Metallic Finishes

Metallic finishes add a layer of metal such as silver, gold or copper to the surface of a custom tin to create a shiny and reflective effect. These coatings can cover the entire surface of the tin or be selectively applied to specific areas, such as logos or text, to create a contrasting effect. One of their main benefits is that their reflective qualities can catch the light and draw attention to the product, which is particularly effective for products that want to convey a sense of luxury, exclusivity or high quality, such as premium foods, cosmetics and gift sets. Combining this versatile finish with other decorative finishes creates a unique and custom packaging solution. For example, a brand may combine a metallic finish with an embossed logo to create a three-dimensional effect, adding depth and dimension to the design.

Bringing More Value with Different Decorative Finishes

Custom tin cans offer brands a wide range of decorative finishes that can enhance the visual appeal, functionality, and overall consumer experience of your packaging. Each option offers unique benefits, from lithographic printing and 3D embossing to metallic finishes. As a company specializing in custom tin cans, Tsing is committed to helping you find the perfect decorative finish for your packaging needs.

-180x180.jpg)

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin