You are here: Home / Tin Structure Display / Tin Craft

As recognized green package products, metal Tin packing and cans mainly based on the physical production process. Different tin can product process can have little difference, but all the basic tin crafts are basically as follows:

Cutting tinplate

After the tinplate is printed, the tinplate will be cut into the rough tin body, lid and bottom according to its printed effect and the required size.

Cutting the edge

This step is to cut the extra edges of the small tinplates cut in step 1.

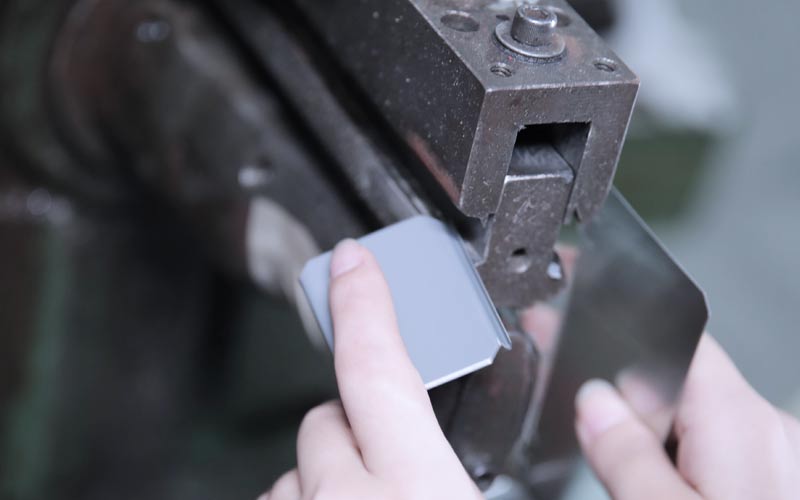

Crimping

Crimping requires the cooperation of a crimping machine to roll the mouth of the small tinplate into a small arc, which is not only for beauty but also prevents hurting from the sharp iron edge. (One more pre-bending process for the inner crimping)

Sealing

It is carried out on the can sealing machine, the can body and bottom are sealed by double crimping. The sealing process is divided into the buckle-in bottom and stuck-out bottom.

It has been hundreds of years since the born of tin can packaging. The products have been more and more perfect in history, and now it’s workmanship technology has been very mature. China has been the major export country of tin cans and our company, Tsing Tin Packing Limit grasps the knowledge of all tin crafts.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin