How does a tin container manufacturer manage bulk customization requests?

Custom tin containers play an important role in various industries, such as food and beverage, cosmetics and pharmaceuticals. Whether you are packaging high-end products or creating a brand experience for customers, the demand for mass customization of tin containers has grown exponentially. Tsing, as a tin container manufacturer, can manage customization and ensure that each custom order meets the required specifications and quality standards. In this guide, we will explore how to manage mass customization requests as a tin container manufacturer so that different users can fully understand the process and advantages of custom tin containers.

Bulk Customization Process of Tin Container Manufacturer

The mass customization process begins with understanding the customer’s specific needs. Tin container manufacturers work closely with customers to determine the size, design, and functionality required for the tin container. Whether it is a custom shape, size, or complex artwork, Tsing will capture every detail to ensure that the final product meets the customer’s expectations. Our customization process is dynamic and can adapt to various requirements, from simple logo placement to complex embossing or full-color printing.

Once the customer’s requirements are determined, the design phase begins. This usually involves creating a digital model or prototype to provide customers with a visual representation of the customized container. Prototyping is an essential step because it allows customers to review and approve the design before mass production begins. We can ensure that the designs meet all industry-specific regulations and quality standards, especially in the food or pharmaceutical industries where packaging integrity is critical.

Manage Material Sourcing for Bulk Custom Orders

For tin container manufacturers, material management is a critical part of meeting bulk customization requirements. The choice of materials not only affects the quality and durability of the final product but also production time and cost. At Tsing, our tin containers are typically made from tinplate, which is a steel core coated with a thin layer of tin. When manufacturing large batches of orders, we carefully plan to ensure timely delivery of materials, especially when dealing with custom sizes or designs. In addition, any additional materials required for decoration or labelling, such as paint, embossing tools, or printed labels, are also considered.

Designing Custom Tin Containers

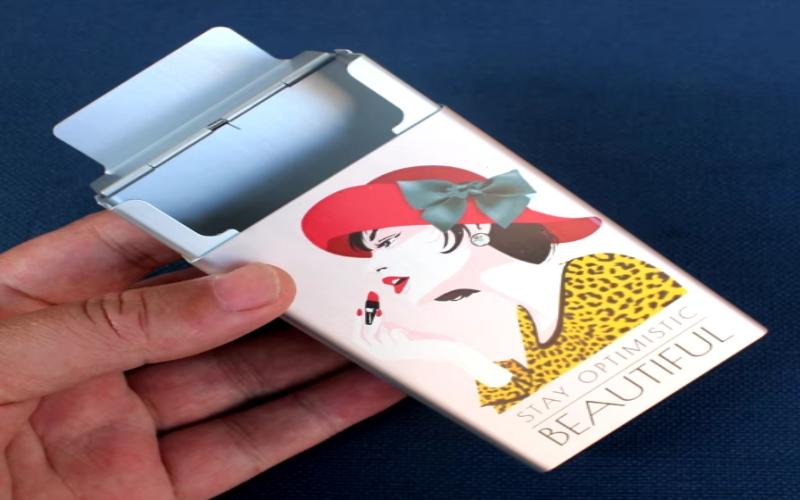

Branding designs are one of the most common customization requests tin container manufacturers receive. Whether it’s a company logo, a specific color scheme, or an intricate pattern, a customized approach can enhance the visual appeal of a tin container and reinforce the brand image. Tsing’s design team communicates closely with you before manufacturing begins to understand your needs and ensures they print or emboss the design on the tin container in a way that is both aesthetically pleasing and functional.

The design stage of a custom tin container often involves multiple rounds of revisions to ensure the artwork matches the customer’s vision. We use printing presses imported from Japan, including screen printing, lithography, and offset printing, and we adjust them to the complexity of the design and the size of the order. In addition, it ensures that the artwork is durable and can withstand the wear and tear of shipping, handling, and consumer use.

Quality Control for Bulk Customization of Tin Containers

Ensuring the quality of each custom tin container is critical, especially when dealing with bulk orders. As a tin container manufacturer, Tsing uses a strict quality control process to ensure that each container produced meets the customer’s standards and complies with industry regulations. The entire quality control process begins with inspecting the raw materials to ensure that they are free of defects and suitable for production. During the manufacturing process, inspectors regularly check the containers for any issues with the shape, design, or material integrity. For custom designs, we conduct thorough inspections to ensure that the pattern, logo placement, and embossing are consistent for each unit. The team also performs tests to ensure that the container is durable and fully functional. For example, if the container is used for food or beverage packaging, it may test its corrosion resistance and ability to seal properly.

Meeting deadlines and logistics for bulk custom orders

As a tin container manufacturer, we also have the ability to manage logistics and plan production schedules to complete bulk custom orders efficiently. For large orders, we provide project management, effective communication with customers, and well-organized production planning. In many cases, this involves coordinating with shipping partners and warehouses to ensure smooth delivery. For larger orders, we can also provide inventory management services, allowing customers to store finished products and distribute them as needed. Tin container manufacturers can effectively manage logistics to ensure they meet bulk customization requests efficiently and with minimal disruption to customers’ supply chains.

Providing you with efficient, high-quality customization capabilities Tin container manufacturer

In short, managing bulk customization requests for tin containers requires a combination of expertise, technology, and efficient processes. Tin container manufacturers are not only good at producing high-quality containers but also at customizing containers to meet the unique needs of each customer. From initial design to material procurement, quality control, and timely delivery, manufacturers play a vital role in ensuring they complete each custom order accurately and efficiently. For businesses in various industries looking to enhance their product offerings with custom tin containers, working with an experienced manufacturer is the key to success.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin