How effective are black metal tins at protecting against light?

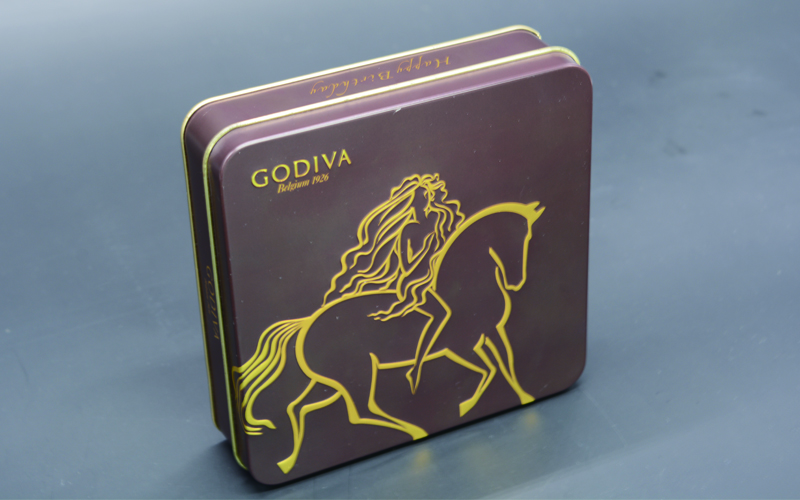

Light can affect the quality and integrity of products ranging from candles to high-end cosmetics, and black metal tins are one of the best ways to preserve the quality and longevity of their contents and are the first choice for effective light blocking. In this blog post, we take an in-depth look at the properties of black metal tins, assessing their effectiveness in protecting products from light.

Composition and light absorption capabilities of black metal tins

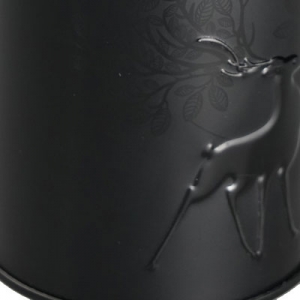

Black metal cans are usually made of tinplate, which are very durable and opaque. The main characteristic of black metal tins is their surface treatment. The black coating, usually an epoxy or acrylic polymer, is achieved through a spray painting or coating that enhances the tin’s natural ability to absorb light. For some foods and beverages that degrade or lose quality when exposed to sunlight, a black coating also minimizes light penetration, thereby maintaining the integrity of the contents and extending shelf life.

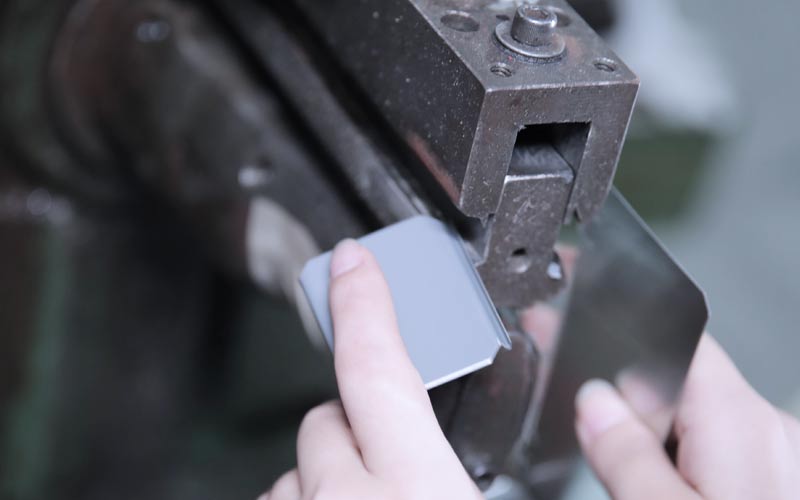

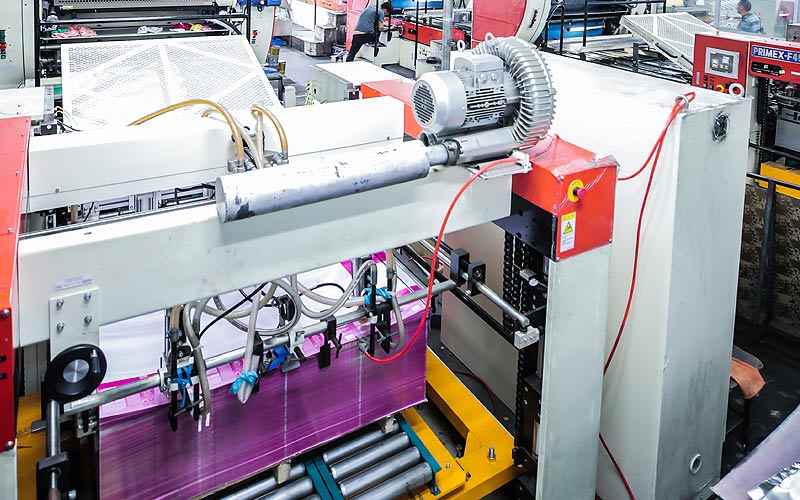

Manufacturing technology for enhanced light protection of black metal tins

A key aspect of enhanced light protection in black metal can manufacturing is the application of specialized black coatings. This coating is typically a polymer-based formulation that contains black pigments, such as carbon black, which provide high light absorption and barrier properties. Choices in the coating formulation can also include additives that enhance adhesion to the metal substrate and UV and chemical resistance to ensure it does not degrade or react with the tank contents. After applying the black coating, we cure the cans in a process that effectively protects against light and ensures the coating’s longevity under various storage conditions.

Comparative analysis with other packaging options

Black metal tins offer better protection from light than other packaging materials such as glass or plastic. Glass often requires additional treatments or tints to achieve similar light protection. Plastic containers vary in their ability to block light depending on their composition. Many plastic containers allow a large amount of light to pass through unless you use additives, and many plastic containers also deform when exposed to light. The inherent opacity and additional coating of black metal cans prevent light exposure, thereby maintaining product quality and shelf life. Unlike breakabGlassass, black metal tins can withstand the rigors of distribution without the risk of breakage.

From a scientific perspective

From a scientific perspective, we can attribute the effectiveness of black metal tins in blocking light to their absorptive and reflective properties. First of all, metals are inherently excellent light reflectors. When treated with dark, non-reflective surfaces, they absorb visible photons, preventing them from reaching the contents inside. This property is essential for products sensitive to UV and visible light. These light-blocking properties are also enhanced by applying a black coating, known for absorbing a wide range of light spectrums, including ultraviolet (UV), visible, and near-infrared light. Black has a higher surface area to volume ratio, which can provide more light absorption sites.

The future of manufacturing and innovation

Incoming ferrous metal tins will likely feature Advanced High-Strength Steel (AHSS), which offers superior durability using thinner gauges. Additionally, nanotechnology could revolutionize coatings by creating ultra-thin layers more effective at preventing corrosion and the interaction between tin and its contents while being fully recyclable. Intelligent technologies such as QR codes and NFC tags also appear in tin designs, blending traditional protection with digital connectivity.

Ultimately

Black metal tins are the best solution for protecting from light. They effectively block light compared to other materials. Combined with their aesthetic versatility and durability, they are the ideal solution for high product quality standards and consumer experience. Ideal for brands.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin