White tin candle containers for long-term storage

In different countries and festivals, candles are essential to create the perfect atmosphere. Therefore, we can use white tin candle containers to store candles properly after we purchase them. It is necessary to determine whether the white tin candle container has the conditions for long-term Storage. In this guide, we will tell you how Tsing ensures the long-term storage ability of the candle container.

The Importance of Using white tin candle containers for Storage

Candle degradation can be accelerated if exposed to light, air, and temperature fluctuations, resulting in discoloration, loss of fragrance, and shortened burn time. It provides a durable and sturdy candle casing, protecting it from external factors such as dust, debris, and accidental damage. White tin candle containers provide excellent protection against moisture and moisture, creating a sealed environment that prevents moisture from penetrating the candle and causing problems such as wick deterioration, wax discoloration, or mold growth.

White tin candle containers made of tinplate

Tsing mainly uses tin plates as a manufacturer of white tin candle containers. Tinplate is a versatile and durable material consisting of thin steel sheets with a layer of tin on their surface. They are durable and corrosion-resistant and can provide many benefits for storing candles, ensuring they can withstand transportation, handling, and environmental Storage. Using white tin candle containers made of tinplate can combine the strength and elasticity of tin with a white finish, adding to the beauty. In addition, the smooth, non-porous surface of the tinplate also provides a sound barrier against moisture, humidity, and other external factors that can affect candle storage.

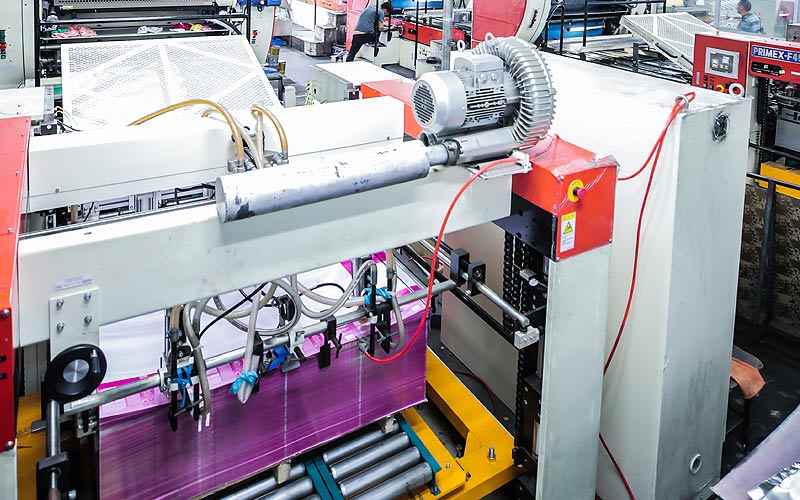

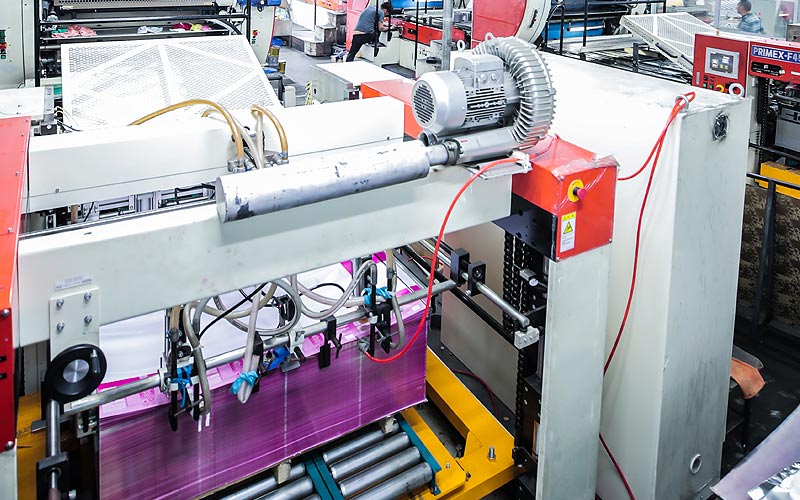

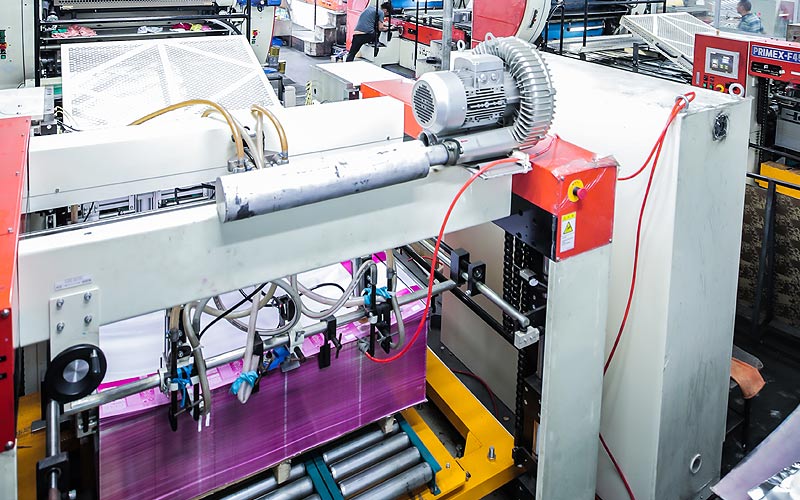

Perform quality assurance and testing

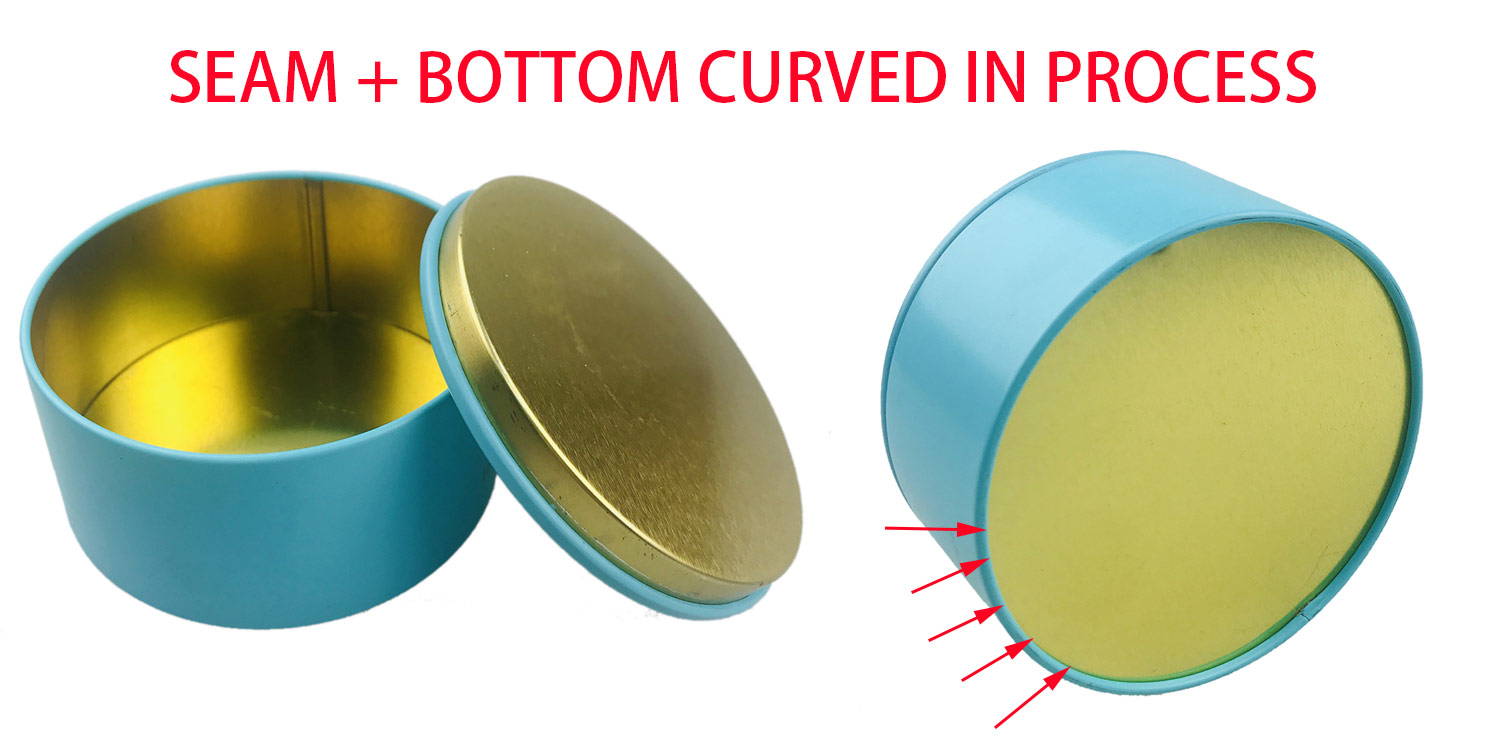

Before production begins, we carefully inspect raw materials, including tinplate, coatings, and other components, to ensure they meet our standards. Then, we will use fully automatic production technology to produce the candle container’s tank body, bottom, and lid. Production errors and product variations can be reduced by automating production. Be able to operate according to the set operating procedures and maintain the stability of the entire production process. We also extensively test finished products to verify performance and durability. This includes testing strength, stability, and resistance to environmental factors such as temperature and shock to ensure durability.

Provide customization options

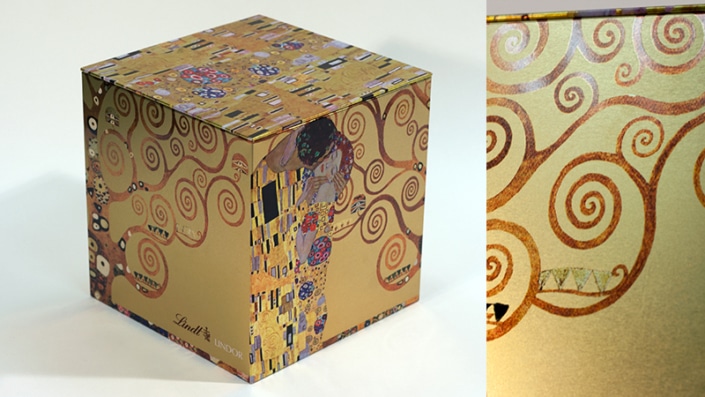

What’s also great about working with Tsing is that we can offer customization options to meet your different needs and preferences for candle containers. These customization options include choices in size and shape. You can adjust the size and shape of the container to ensure it fits your storage space. Whether you prefer a traditional cylindrical container or a modern square or rectangular shape, there is something for everyone. In addition to size and shape, various finishes are included to enhance different decorating styles. Choose matte, glossy, textured, or metallic finishes to suit your branding requirements or design theme. The lid options include screw-in lids, sliding or hinged lids, and more.

Build customer support and trust!

When you choose Tsing to manufacture your white tin candle containers, our team of experienced professionals guarantees you excellent customer support from initial concept development to final delivery. Whether you have questions about product specifications, customization options, or logistics, Tsing provides guidance and assistance for a satisfying customization experience.

Get a long-term storage experience!

Candle containers are a good choice for any user or brand that wants to store candles for a long time. Tsing has many years of experience in custom tin containers, and you can trust us to create white tin candle containers that are durable enough for you.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin