What are the manufacturing processes of tin box manufacturer?

Tsing Tin Packaging is a tin box manufacturer providing complete customization services. Our company has over 200 skilled workers and a monthly production capacity of over 8 million pieces. Many customers want to know what our manufacturing and production processes are. The following section briefly introduces mold design, printing, production, packaging, and logistics. Let you intuitively feel our production and understand our advantages.

Mold design for tin box manufacturer

Tsing currently has more than 500 sets of molds for customers to choose from, and our molds can produce most of the ordinary tins presently seen on the market. If our current molds don’t fit your custom metal cans, we will design your mold for you. We will have professional designers communicate with you about the custom images you need and make mold structure drawings and 3D structural images through CAD. After confirming with you, we will carry out mold cutting, 3D bending, mold assembly, and pre-mass production.

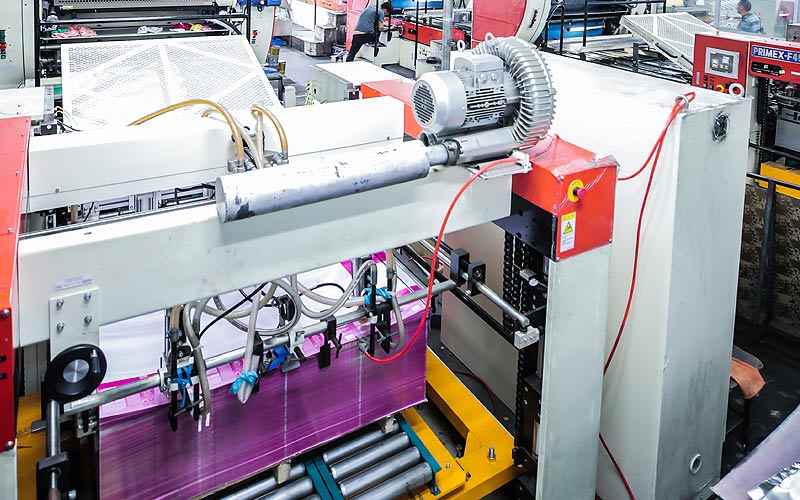

Printing technology for tin box manufacturers

During the printing process, we use the latest printing machines from Japan, which can produce various metal prints daily on the market, such as CMYK or Pantone, matte or glossy. This ensures precise and intricate details and vibrant colors on your tin boxes. Facing different transportation and storage environments, we use specially formulated printing inks and coatings to ensure that the prints on the tin boxes are durable, fade-resistant, and scratch-resistant. In addition, according to your requirements, One More printing effects can be provided for free for you to choose from.

Fully automated production line

With the advent of the automation industry, we have upgraded our production lines to fully automatic production lines, including automatic can lid production lines, automatic can body production lines, and automatic can bottom production lines. The automatic stamping processing technology shows good interchangeability and energy saving and can realize thin-walled, lightweight, rigid, and complex-shaped parts that are difficult to produce by other processing methods. Automating production can reduce errors and product differences. The operation will be carried out according to the set operating procedures so that the stability of the product can be maintained throughout the production process. It can also meet different types of design.

Packaging and shipping

Our packaging and shipping processes are carefully designed to protect our tin boxes during transportation. Use high-quality packaging materials such as cardboard boxes, bubble wrap, foam padding, and protective sleeves to provide multiple layers of cushioning and insulation around the iron boxes to protect them from damage during handling and transportation. In addition to protective packaging, we prioritize branding and presentation in packaging design. Custom packaging options will also be available, allowing customers to personalize their packaging with their own branding and messaging. After packaging is completed, we will efficiently transport it to global destinations by road, sea, air, and other international logistics methods.

Provide you with high-quality iron box packaging

Tsing’s manufacturing process will involve mold design, printing technology, fully automated production lines, and international logistics and transportation. We will continue to create products to meet the diverse needs of different customers. We can create it exclusively for you, whether it is used for packaging food, gifts, cosmetics, or other products.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin