What are the benefits of using metallic or textured finishes on black tins?

The choice of materials and surface treatments in tin packaging tin significantly affect the marketability and consumer appeal of the product. Black tins are suitable for packaging and storing a variety of teas, coffees, candles, etc. Their different designs and functional options make them a popular tin packaging choice for various industries. However, these tins will benefit more significantly when combined with metallic or textured finishes.

Enhanced visual appeal of black tins

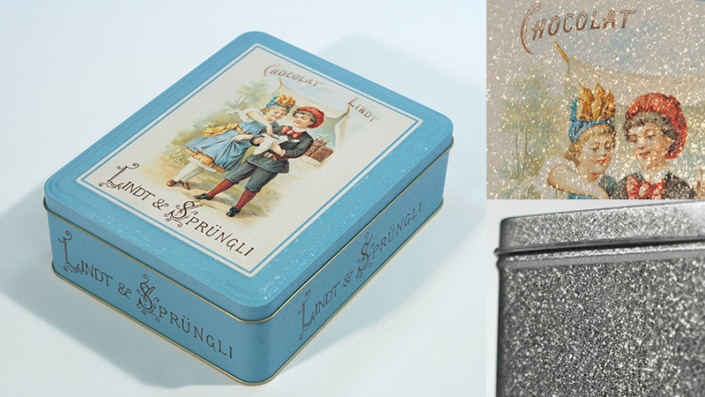

The first benefit of applying metallic or textured finishes on black tins is enhanced visual appeal. For example, metallic finishes can contrast against a deep black background, making the packaging more eye-catching. This visual appeal can attract potential customers, especially in retail environments where products compete for attention on crowded shelves. Textured finishes also add depth and interest to packaging. Whether matte, glossy, or embossed textures, these elements create a tactile experience for consumers. The combination of texture and color can bring a unique feeling, attracting customers to learn more about the product.

Improve brand recognition and differentiation

In a competitive market, it is essential to improve brand recognition. Using metallic or textured finishes on black tins can help companies differentiate their products from competitors. Unique finishes not only differentiate a brand but can also convey a sense of quality and sophistication. Consumers often associate metallic finishes with luxury and high-end products. This association can elevate a brand’s image, allowing it to command higher prices and foster consumer loyalty. Similarly, textured finishes can evoke a sense of craftsmanship and authenticity, appealing to consumers who seek quality and uniqueness in their purchases. By combining these finishes, brands can reinforce their identity and create a powerful visual statement.

Improving Black Tins Protection for Products

Beyond aesthetics, finishes on black tins play a functional role. Metallic coatings can enhance the protective properties of packaging, making it more resistant to moisture, UV rays, and other environmental factors. This extra protection is essential for products sensitive to light and moisture, such as food or cosmetics. Textured finishes can also improve the overall durability of black tins. The added layer of texture helps reduce scratches and wear during handling and shipping. By enhancing the packaging life, companies can ensure their products arrive in optimal condition, ultimately increasing customer satisfaction.

Versatility for Different Industries

Black tins are available in metallic and textured finishes, making them ideal for various industries, including food and beverage, cosmetics, and gift packaging. This adaptability allows companies to leverage these finishes’ aesthetic and functional benefits to suit their brand identity and product needs. The choice of finish can significantly impact consumer perception; for example, a specialty coffee brand might choose a sleek metallic finish to convey freshness, sophistication, and premium quality. This visual appeal can enhance the overall consumer experience, prompting customers to associate the product with high standards.

Through a textured finish, skincare brands can create a tactile experience that evokes a sense of luxury and indulgence. This choice differentiates the product on the shelf and strengthens the emotional connection between the brand and the consumer. Additionally, black tins can be effectively used for seasonal promotions, limited editions, or holiday-themed packaging, further increasing their appeal across different market segments.

Future Trends in Packaging and Design

As consumer preferences evolve, the packaging industry is also changing, reflecting broader shifts in societal values and technological advancements. One of the most prominent trends is the growing demand for personalization and customization, which is expected to significantly increase the popularity of metallic and textured black-tin finishes. Brands increasingly seek to create packaging that stands out on the shelf, reflects their values, and connects with consumers deeply emotionally. This desire for individuality drives companies to explore innovative design strategies to make their products memorable and meaningful. In addition, sustainability remains a crucial factor influencing packaging design. As consumers become more environmentally conscious, brands prioritize eco-friendly materials and production processes when looking for black tins. Black tins made from recycled or sustainable materials can attract ecologically conscious consumers.

Multifaceted Benefits for You

From enhanced aesthetics and increased brand awareness to enhanced product protection and sustainability, these designed finishes can provide significant advantages to companies in various industries. By adopting these innovative packaging solutions, different businesses can create eye-catching packaging that stands out on the shelf and aligns with consumer expectations and values.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin