How to Design Custom Tea Tins for Different Market Segments?

For tea brands, especially those targeting different market segments or tea manufacturers, creating unique and attractive tea tin packaging is essential. Therefore, these customers usually choose to design custom tea tins, which is a very artistic job for us, combining aesthetics, functionality, and brand building. At the same time, custom tea tins can not only protect the product but also serve as a powerful marketing tool to influence consumers’ purchasing decisions when buying tea.

Target Markets for Custom Tea Tins

The first step in designing a custom tea tin is to understand your target market. Users in different markets have unique preferences and needs, and your tin packaging should reflect these differences. For example, a luxury tea brand may focus on elegance and sophistication, while a brand targeting a younger audience may choose a vibrant and fun design. Therefore, market research is needed to understand consumer preferences and purchasing behaviors. This research will help you create packaging that resonates with your target audience and enhances their overall experience with your brand.

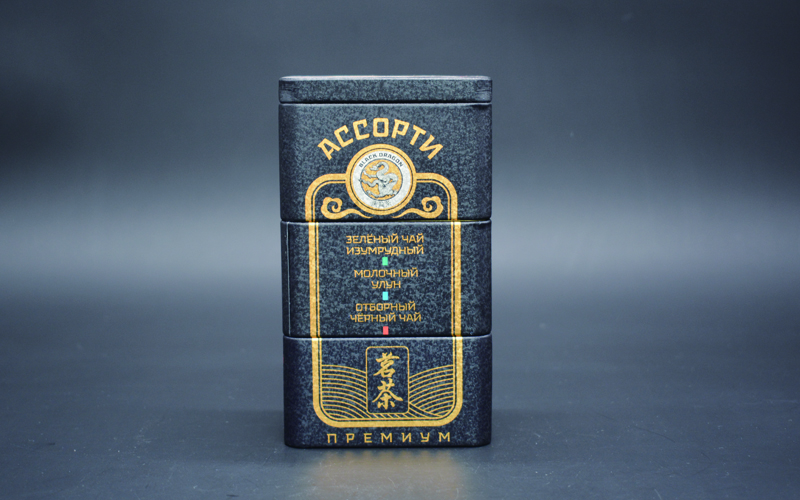

Designing Custom Tea Tins for the High-End Market

The high-end tea market needs to exude a sense of elegance and sophistication in packaging, and the custom tea tins for this market should reflect the high quality and uniqueness of the product. Therefore, you can use premium materials such as brushed metal or high-gloss finishes to attract the eye and make the look and feel more luxurious. Incorporating elements such as gold or silver embossing, intricate patterns, and high-quality printing techniques can increase the perceived value of the product. In addition, high-end tea tins often have exquisite and unique shapes that set them apart from standard packaging. Some limited-edition designs or collaborations with well-known artists can also attract this market and add collectible value to the product.

Custom Tea Tins for Health-Conscious Consumers

Health-conscious consumers are more concerned about sustainability and transparency. When designing custom tea tins for this market segment, it is necessary to use environmentally friendly materials such as recyclable metals or biodegradable coatings. The design should convey the health benefits of tea and the brand’s commitment to environmental responsibility. A simple, clean design with green tones can effectively communicate these values. Adding some transparent elements to the tea tins, such as lids with clear windows or clear labels, allows consumers to see the product. Adding detailed information about the origin, ingredients, and health benefits of the tea on the tin can also attract users in this market.

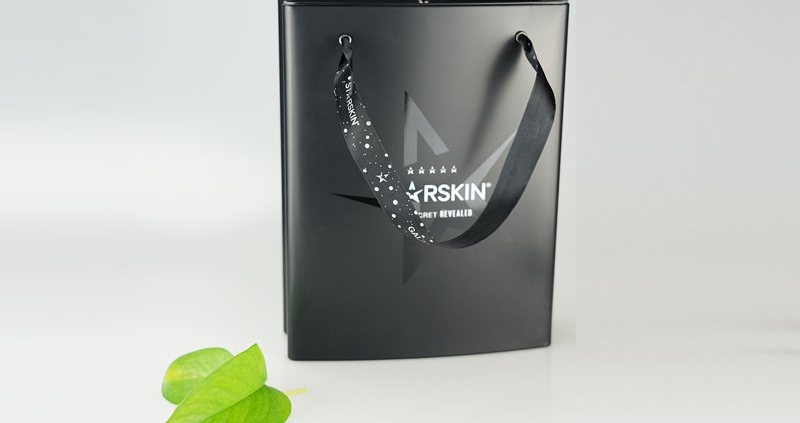

Youth Market

The new generation of young consumers likes bold, vibrant and innovative packaging designs. Custom tea tins for this market should be visually striking and interesting, reflecting current trends as well as cultural references through their design. Utilizing some bright colours, quirky illustrations and modern fonts can make your tea tin packaging stand out on the shelf and for online trading brands. Adding some interactive elements to the tins, such as QR codes, can also attract younger consumers in the Internet age. By creating dynamic and visually appealing custom tea tins, you can attract younger consumers who value creativity and individuality.

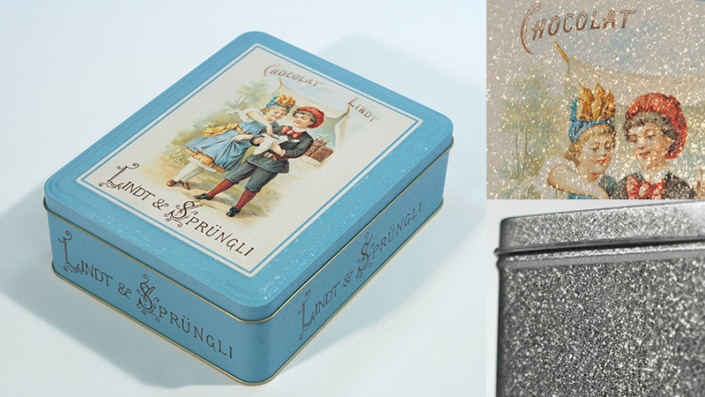

Gift Market

Tea is a popular gift, and customized tea tins meet both aesthetic and practical needs. Suppose you are planning to customize a batch of tea tins for gifting. In that case, the packaging should have a festive or elegant look that is suitable for various occasions such as holidays, birthdays or corporate gifts. The gifting experience can be enhanced through some high-quality materials and finishes, as well as thoughtful design elements such as ribbons, tags or personalized messages. When considering creating a themed series or special edition tea tins, these tins can be designed with seasonal designs to make the gift more special. The addition of compartments or partitions within the tin can also add a practical element, allowing the recipient to store different types of tea or accessories.

Make your tea caddy accessible to users in different markets

When designing custom tea tins, by considering the unique preferences and needs of users in each market segment, from high-end consumers to health-conscious groups and young audiences, we can create custom tea tin packaging that resonates with consumers. Custom tea tins can not only protect the product but also serve as a powerful marketing tool to enhance the tea brand image and consumer experience.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin