How can I ensure the print quality on my custom printed tins?

Custom printed tins are a popular choice for many brands and wholesalers for packaging, promotion and promotion. They will show their products’ differentiation and brand characteristics through customization and present different effects through different printing methods. Therefore, printing quality is critical, especially for those brands that purchase large quantities. If the quality of the entire batch is problematic, it will seriously affect the subsequent use. In this guide, we will share how we ensure the printing quality of custom printed tins.

Use food-grade inks in custom printed tins

We prefer to use food-grade inks in custom printed tins, which can ensure that the inner wall of the iron box can indirectly contact food, and the printing inks are all certified by the international FDA, LSGB, etc. Food-grade inks are used to ensure the safety of custom printed cans. These inks do not contain harmful substances such as heavy metals and VOCs. After being formulated, they can show excellent anti-migration properties, ensuring they will not transfer or penetrate the food stored in the tin. This feature can maintain the integrity and quality of the packaged food and prevent any interaction between the ink and the food.

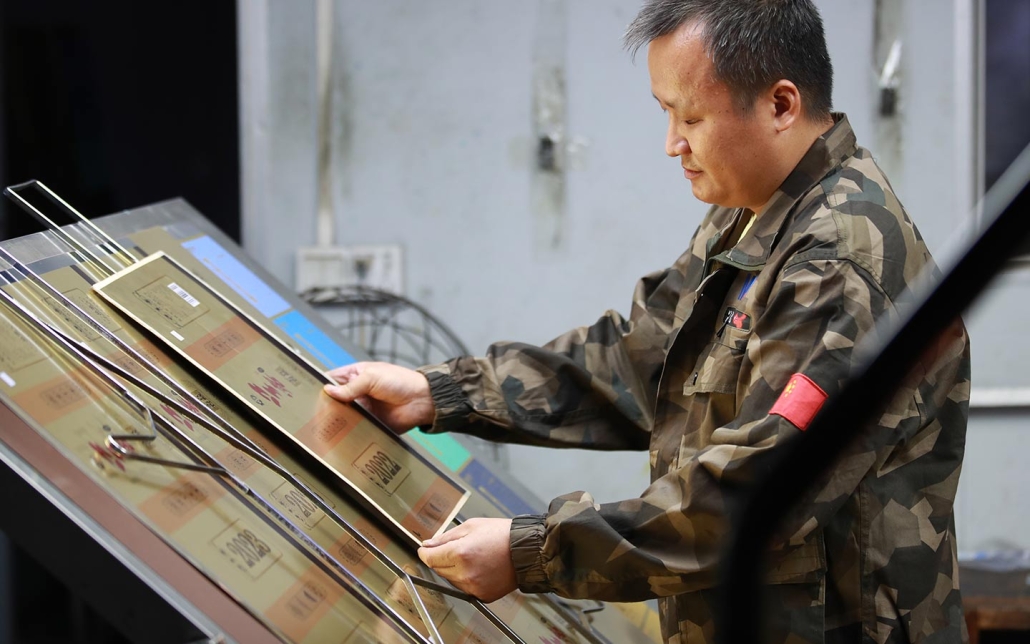

Use original digital letterpress printing

We use original German digital letterpress in a custom printed tin printing process. It ensures crisp, high-resolution graphics, allowing it to print complex patterns, fine lines, and small text with excellent clarity and accuracy. This technology can also create different tactile textures on the printed surface. Unlike traditional digital printing methods that produce flat images, letterpress printing adds depth and dimension to the printed design by pressing the ink into the substrate, enhancing the tin’s visual appeal. Digital letterpress printing also reflects an efficient and fast production process, reducing setup time.

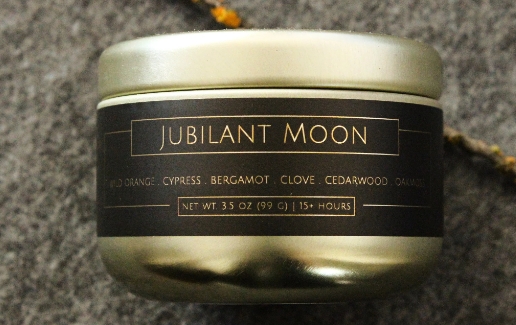

Using CET International Standard Color Printing

We also use CET International Standard Color Printing in custom printed tins, which can support a wide color gamut, allowing us to reproduce bright and realistic colors on custom printed cans. Whether a brand logo, complex graphics, or subtle gradients, our printing technology can capture and reproduce the full spectrum of colors, ensuring that the final printed tins meet your aesthetic standards. At the same time, using CET International Standard Color Printing can also provide consistent color reproduction in different printing jobs and production runs. To ensure that the color accuracy of custom printed tins matches the specified target value.

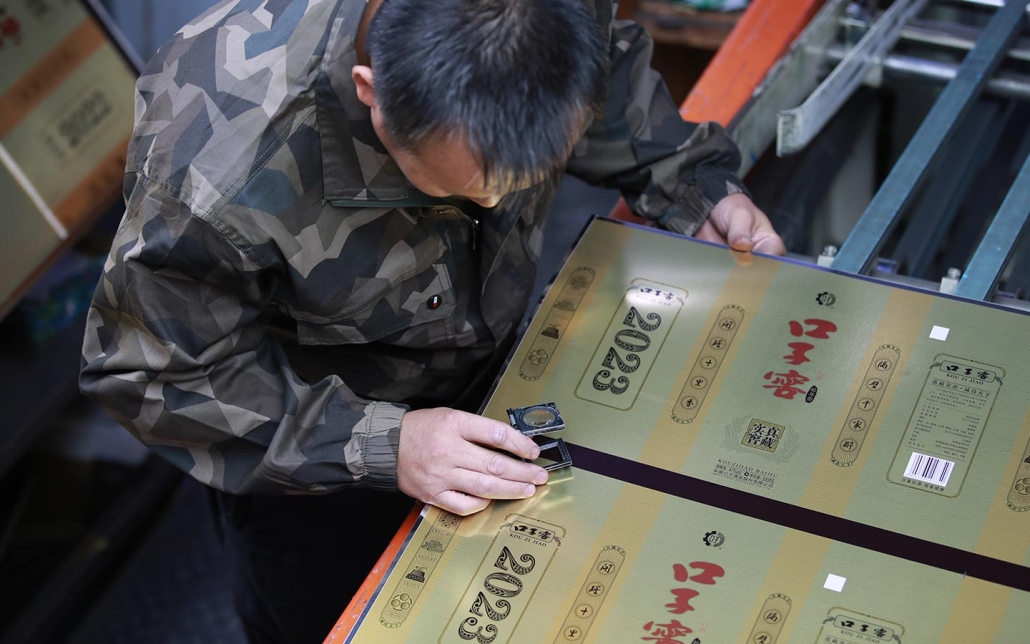

Using Fuji Printing Machines in Custom Printed Tins

Fuji Printing Machines in Japan have advanced print heads and imaging systems to provide ultra-high-resolution prints. This ensures precise and sharp details and vivid colors, allowing us to achieve complex and detailed text and graphics on custom printed tins. At the same time, it provides the flexibility of variable data printing capabilities, allowing personalized and customized printing on each tin.

They also use advanced color management technology and calibration processes to ensure accurate and consistent colors. We achieve precise color matching and consistency across different printing jobs and production runs by following standardized color profiles and calibration procedures. With our high-speed printing and automated workflow capabilities, we can easily handle large-volume orders.

Let you harvest unexpected printing quality

To ensure the printing quality of our custom printed tins, we use food-grade inks, German original digital letterpress and CET international standard color printing, and Japanese Fuji printing presses to ensure color accuracy and harvest high-standard printing processes so that your creativity can be better presented in front of you.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin