How to avoid printing deformation and stripes when printing on cookie tins?

Cookie tins are more than just containers for cookies; they are the first impression of a brand, a gift worth giving, and a symbol of product quality. Print distortion, banding, or streaking on the lid or body of a tin can can have immediate consequences, including reduced shelf appeal, customer complaints, and sometimes even expensive rework. To address these printing issues, Tsing, as a tin can manufacturer, utilizes advanced printing technology, including a German digital letterpress CTP workflow, CET international standard color printing, and Japanese Fuji printing presses. This equipment and these standards, when properly applied, can significantly reduce color mismatches and mechanical artifacts.

Preventing Printing Artifacts in Cookie Tins with Prepress and Design

Most printing issues stem from prepress decisions. Careful design of artwork and die lines can significantly reduce the likelihood of streaking, moiré, or noticeable distortion after ink contacts the metal. Cookie tin are often cylindrical, rectangular, or compound curved surfaces. When applying patterns to curved panels or lid edges, vector geometry and image tiling must consider stretching and seam placement. Use die lines that conform to the actual shape, generated from a 3D wrap or flat pattern provided by the cookie tin manufacturer, rather than a generic flat template. When designing lids, avoid using precisely straight horizontal bands in seam areas, as seams and embossing can create reflections that cause any slight misalignment to appear as visible streaks. Also, avoid using fine banded gradients or extremely fine halftones in areas where the print path skirts seams, sequins, and hems.

Substrate preparation and surface treatment to avoid irregular ink flow

The behavior of ink on metal depends primarily on the surface of the substrate. Inconsistent substrate preparation is the primary cause of post-print distortion and streaking. Tinplate and aluminum alloys vary in thickness, embossing, and substrate surface treatment. Variations in coil thickness or surface roughness can result in localized differences in ink distribution and drying, which may manifest as streaking. When purchasing bulk tin packaging, specify tight coil tolerances and request a coil test certificate to ensure the packaging’s quality. For critical, high-end printed cookie tins, consider pre-selecting coils from the same production batch to minimize surface variations.

Oil or contaminants can cause inconsistent ink beading and drying, creating repellent areas. Therefore, coils must be degreased and cleaned before printing. Tinplate and some aluminum products require passivation to stabilize the surface and ensure ink adhesion. Use a tested primer or conversion coating that matches the ink system and final finish. Inconsistent primer thickness can lead to localized variations in ink absorption and may cause streaking. Many printed cookie tins require a primer or undercoat to achieve a uniform white background, ensuring color accuracy. Tsing uses the CET standard color workflow to ensure consistent primer application and colorimetry across all jobs.

Printing Technology, Press Setup, and Mechanical Stability for Cookie Tins

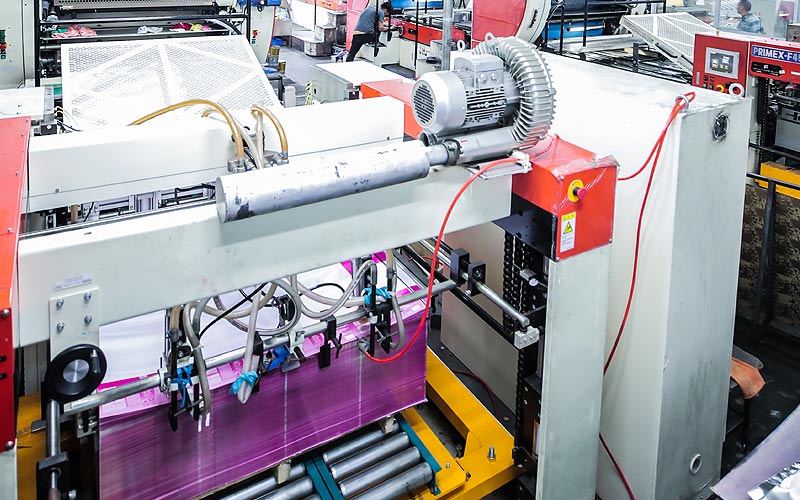

Factors in the printing process are the most direct cause of banding and distortion. Even with perfect prepress preparation and substrates, poor press setup can lead to visual defects on printed cookie jars. Different printing technologies are suitable for different effects. Offset printing achieves high-fidelity image reproduction, gravure printing creates deep, solid, and metallic finishes, and digital letterpress printing offers fast color changes and stable registration. Tsing uses German digital letterpress CTP presses and Japanese Fuji printing presses, both industry-proven platforms for high-precision tin can printing. Uneven printing plates often cause streaks, so we regularly maintain cylinder profiles, check gravure screens for wear or clogging, balance nip pressure on the cylinders, and promptly replace worn rubber or blanket cylinders.

Printing plates produced using CTP minimize prepress variations. However, plate mounting and cylinder concentricity remain crucial. Improper plate mounting, slight tilt, or uneven plate tension can result in repetitive streaks in the design. Tsing’s German digital letterpress CTP and CET standards ensure rigorous control at this stage.

Color management, CET standards, and spectral control eliminate visible streaks.

Streaks are often more noticeable when colors shift or when adjacent tones have different spectral reflectances. Strict color management can prevent noticeable streaks. Therefore, during the printing process, we employ international standard workflows and ICC profiling in accordance with the CET standard. To achieve repeatable results on printed cookie tins, we calibrate the press to the ICC profile based on the precise substrate, primer, and ink set. We create press characteristics and generate linearization curves under production conditions to minimize tone mapping shifts and avoid visible banding.

For spot colors on cookie tins, we use standardized spot color formulas and control the dispersion of metallic pigments. We also avoid over-coverage of metallic colors in seams or embossed areas. If such specialized colors are critical, we utilize dedicated printing stations and print-side samples to prove the metallic appearance, thereby preventing unexpected results.

Process control, inspection, and finishing ensure high-quality production runs.

Quality assurance practices can detect and prevent banding before full production, ensuring that printed cookie tins are shipped defect-free. As a professional tin manufacturer, we install high-resolution cameras with line scan capabilities to detect banding, color variations, and register drift in real time.

We also utilize SPC tools to correlate ink density, temperature, and machine settings with defect rates. When streaks are detected, the corresponding timestamp history is checked for signs of unstable operation, cylinder temperature variations, or plate anomalies. Post-press processing stages, such as varnishing, UV curing, and embossing, can mask or amplify printing defects. For example, a thick varnish layer can reduce noticeable banding by providing an even surface gloss, but uneven application can create new streaks. Therefore, embossing the printed surface changes reflectivity, and proper alignment and placement of the embossing die are crucial to avoid highlighting minor registration errors.

Bringing Perfect Printing to You

Avoiding print distortion and streaking on cookie tins requires a systematic approach, starting with high-quality artwork and die lines, controlling the substrate surface, configuring appropriate printing technology and settings, applying strict color management, and adhering to a CET-compliant workflow. This is completed with process control and robust post-press finishing. Tsing eliminates common root causes of streaking and distortion by utilizing German digital letterpress CTP, CET-compliant color printing, and Fuji printing presses from Japan.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin