What are the best custom tin can designs for airtight storage?

In product packaging studies, up to 35% of spoilage is caused by poor sealing and moisture intrusion. To address this, a custom tin can design tailored to preserve freshness, flavor, and shelf life is necessary. Custom tin can designs range from gasket-lock snap-on lids to vacuum-sealed screw-on lids, providing reliable protection against air, moisture, and contaminants. These seal-on lids feature consistent sealing performance, ensuring your product remains stable from the factory to the consumer.

Snap-on lids in custom tin can designs

One of the most effective custom-sealed tin designs is a snap-on lid with a gasket. For example, a food-grade silicone or EPDM gasket, when injected into the lid, creates a resilient seal around the edge of the can’s mouth. In addition, a snap-on undercut design provides tactile feedback to ensure a proper seal. We specify a one mm-thick, 30 Shore A silicone liner bonded with a heat-resistant adhesive. This configuration withstands temperature fluctuations between 0°C and 50°C, ensuring a vapor transmission rate of less than 0.1 g/m2/day. Additionally, manufacturers can customize the gasket shape to be flat, ribbed, or dovetailed, depending on the product’s viscosity and shelf life requirements. By combining a snap-lock structure with an integrated gasket, custom cans remain airtight even after repeated opening and closing.

Custom Tin Can Designs with Screw-Top Vacuum Seal Configuration

Another high-end option for sealed storage in a custom tin can design is a screw-top vacuum seal configuration. The can body and lid feature precision-machined threads, allowing users to screw the lid down for air venting and partial vacuum creation, extending shelf life. An EPDM O-ring sits in a machined groove within the tin body, maintaining vacuum levels down to -0.8 bar long-term. The anodized thread surface minimizes wear, keeping tolerances within ±0.05mm even after repeated use. Suitable for high-value contents such as high-end teas, coffee beans, and pharmaceuticals, the sealing performance of this design directly translates into more extended shelf life and consistent flavor, giving brands a market advantage.

Double-wall insulation with a seal

For products that are sensitive to temperature and humidity, custom tin can designs can feature double-wall insulation with seals. For example, a 5mm air gap between the inner and outer tinplate walls creates a thermal barrier that slows heat transfer, thereby maintaining a constant temperature inside the can. The design incorporates a removable, FDA-approved PTFE seal between the tin walls to block moisture ingress while enabling simple cleaning and sterilization. In addition, this double-wall design reduces condensation on the outside of the can for refrigerated products, preventing dripping and corrosion. Combined with a precision-fit lid, these custom tin cans provide sealed storage for temperature-sensitive products such as specialty chocolates, cosmetics, or artisan cheeses, maintaining quality and preventing spoilage in changing environmental conditions.

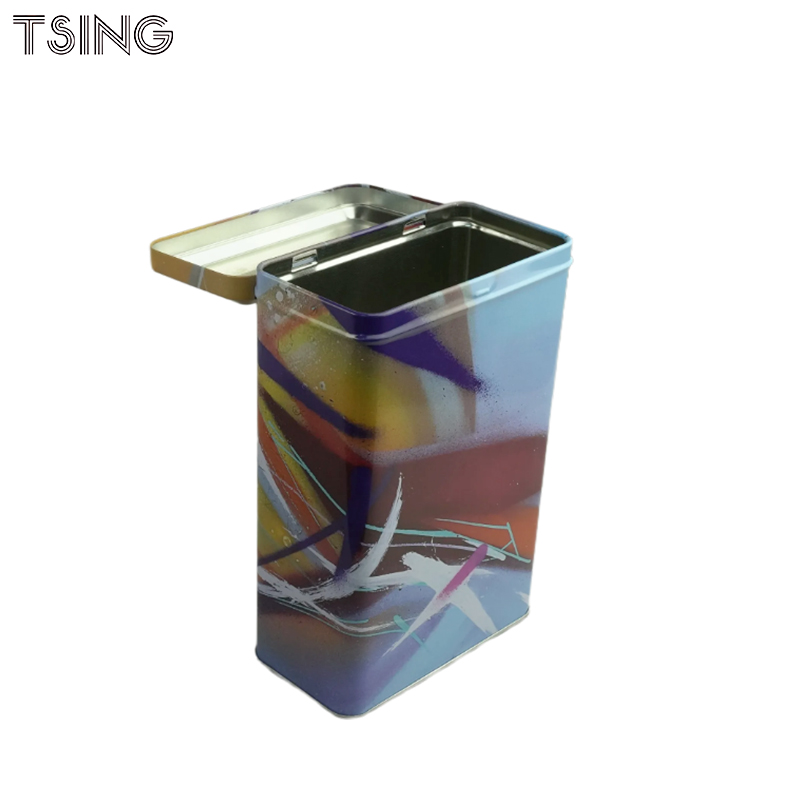

Hinged lid design with compression seal

Hinged lid custom tin can designs allow for quick access while maintaining an airtight seal through a compression seal. For example, heavy-duty stainless steel hinges keep the lid attached during repeated use. The design incorporates an internal silicone gasket that compresses against the can rim with every closure. We will select hinges with a service life of more than 50,000 cycles and design the inner edge of the lid to compress the gasket thickness by approximately 25%, thereby ensuring a reliable seal without excessive closing force. Additionally, magnetic locks can be integrated to keep the lid in place, enhancing user convenience. This hinged lid design allows you to combine quick access with airtightness, making it very suitable for food tins, candle tins, and collectibles that you need to open frequently while maintaining their internal state.

Bring the best sealing to the packaging.

The best seal design in custom tin can design can utilize a sealing gasket lock lid, a screw lid vacuum seal, double insulation, and a hinged lid compression seal. These designs can prevent the intrusion of oxygen and moisture, protecting the flavor and potency of the product and there by extending its shelf life while maintaining product quality throughout the production-to-consumption process. I recommend choosing a design that meets the product’s sensitivity to air, moisture, and handling requirements to better protect the product.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin