Wholesale candle tins supplier: Precision-matched lid fits and tolerances

Common defects associated with candle tin lids include loose lids that fall off during shipping, tight lids that break when opened by customers, and misaligned lids that leave gaps. For any brand selling 100,000 wholesale candle tins annually, a 7% defect rate means 7,000 units wasted and tens of thousands of dollars in material and labor costs. As a wholesale candle tins supplier, Tsing has seen these costs put brands in a difficult position and erode trust in major brands. The root cause? Most wholesale candle tins supplier fail to consider lid fit, using vague tolerances that lead to inconsistent products. Tsing, on the other hand, focuses on precision at every stage of production, ensuring our wholesale candle tin lids fit so perfectly that customers barely notice the “gap” between the lid and the tin.

Why is a precise lid fit and tolerance so crucial to your brand?

For candle brands, the lid is more than just the “top” of the tin; it’s a critical component to the product’s functionality and perceived quality. A poorly fitting lid from a wholesale candle tin supplier can directly impact customer experience for the following reasons:

Consumer Trust: Loose lids can lead customers to believe your product is “cheap” or poorly made—according to an NCA survey, 43% of shoppers would return a candle with a faulty lid. Conversely, tightly aligned lids convey care and quality.

Product Protection: Misaligned lids can allow dust, moisture, or insects to enter the candle tin, damaging the candle, especially soy or beeswax candles, which absorb odors. We once worked with a brand that experienced mold on 12% of its candles because their previous supplier’s lids had a 0.5mm gap.

Transport Durability: Loose lids can rattle during shipping, scratch the exterior of the candle tin, or damage labels. This can force you to add additional packaging, increasing costs.

Thus, tolerance is key. Most wholesale candle tin suppliers maintain a ±0.3mm tolerance on the lid and tin diameters, which is enough to create visible gaps or narrow areas. Tisng adheres to a strict tolerance of ±0.1mm, so small it’s barely noticeable to the naked eye.

Tsing’s Tolerance Standards as a Wholesale Candle Tins Supplier

To understand Tsing’s advantages over other wholesale candle tins supplier, first understand the industry-standard lid fit:

Diameter Tolerance: Both the tin lip and lid rim are ±0.1mm. For a standard 8-ounce candle tin, this means the lid width cannot exceed 65.1mm or be less than 64.9mm to ensure a snug fit.

Height Alignment: When closed, the lid rim is precisely aligned with the tin top by 0.2mm, eliminating any “wobble” or unevenness. This prevents the lid from tilting to one side.

Sealing Pressure: When the lid is closed, it applies 5-7 psi of pressure, which is sufficient to keep moisture out but allows customers to open it easily.

How does Tsing achieve this? We utilize two key tools that most wholesale candle tin suppliers overlook: First, our lid and jar molds are CNC machine-cut to an accuracy of ±0.1mm, far exceeding manual machining. During production, we laser scan every 100 units to check diameter, alignment, and sealing pressure. If the deviation is as little as 0.1mm for each unit, we immediately adjust the mold.

For example, when producing 4-ounce wholesale candle tins for a boutique brand, our laser system detected a 0.12mm discrepancy in lid diameter after 500 units. We recalibrated the mold, and the following 10,000 units were flawless, with no returns.

Manufacturing Processes Expected from a Wholesale Candle Tins Supplier

To ensure optimal precision, Tsing is integrated into the production process for wholesale candle tins. Here’s the step-by-step process we use to provide a consistent lid fit:

Step 1: 3D Design and Mold Engineering

We first create 3D models of the tin and lid and test their fit in digital simulations. This allows us to identify potential fit issues, such as excessively thick lid rims, before we even start molding.

Step 2: Material Control, Using Food-Grade Tinplate

We source 0.23mm thick food-grade tinplate for the tin bodies and lids. Material warping is the primary cause of lid failure. Even a precision lid won’t fit if the jar opening is slightly oval. Our material inspectors check the flatness and thickness of each batch.

Step 3: CNC Production and Real-Time Inspection

Our production line uses CNC presses to form tin cans and lids. Each machine has built-in sensors that measure the diameter of each product during production. If the tin opening is 65.11mm, the machine automatically pauses to prevent defective products from moving to the next step.

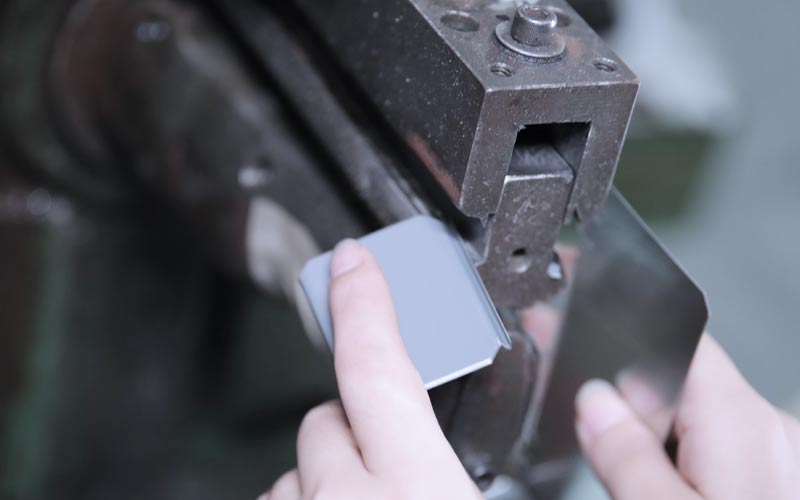

Step 4: Manual Fit Testing (Per Batch)

Before shipping, our quality team manually tests 1% of each order by opening and closing the lids to ensure durability.

Through these production processes and steps, we ensure that every lid on your wholesale candle tin arrives perfectly fitted.

How does Tsing’s precision solution mitigate the risk of brand defects?

While numbers speak for themselves, actual production results are even more critical. A client we previously worked with switched to Tsing after experiencing lid-fitting issues with their candle jars after ordering from another wholesale candle tins supplier.

This client is a mid-sized US candle brand that wholesales 150,000 candle tins annually (in both 8-ounce and 12-ounce sizes).

The previous supplier’s issue: a defect rate as high as 8% due to loose and misaligned lids. They spent $36,000 annually on replacements and lost 10% of their retail customers due to quality complaints.

Tsing’s solution: We produced the tins to a tolerance of ±0.1 mm, added laser measurement inspections, and performed leak testing.

The result was a 0.5% defect rate, saving $34,500 annually. Retail customers returned, and customer reviews mentioning “perfect lid fit” increased by 28%.

How do you audit a supplier’s lid-fitting accuracy?

Not all wholesale candle tin suppliers claiming “accuracy” actually deliver. To avoid costly mistakes, ask yourself these four questions before working with a supplier:

What is your tolerance for the candle tin lid and body diameter? Avoid suppliers who claim “we meet industry standards” and insist on a specific number (e.g., ±0.1mm). Do you use CNC tooling and laser measurement? Can you provide defect rate data for the cap fit? A reputable supplier will share recent batch data. Are caps tested for leaks, durability, and stacking?

Tsing, as a tin can manufacturer, openly answers these questions. We share our tolerance specifications, offer virtual tours of our CNC and laser equipment, provide defect rate reports, and send sample tins so you can test cap fit in person.

Guaranteed precision in every batch of candle tins

For candle brands, choosing a wholesale candle tin supplier isn’t just about price; it’s about avoiding the hidden costs of mismatched lids: wasted material, lost sales, and damaged reputation. Tsing’s focus on precision-fit lids (±0.1mm tolerance), CNC manufacturing, and rigorous testing ensures your wholesale candle jars are ready to sell, with zero defects and zero hassles.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin