5 Things Every Brand Should Know Before Choosing Custom Printed Tin Cans

Product packaging design influences consumer purchasing decisions, and custom printed tin cans have a brand impact three times greater than standard packaging. For some gourmet food brands, this means a well-designed tin can serves not only as a container but also as a marketing tool, potentially increasing repeat purchases by 25%. However, choosing the wrong custom-printed tin can or one that does not meet your needs can turn this opportunity into a disaster by overlooking key details. As a tin can manufacturer, we have distilled a few tips to consider when purchasing.

For custom printed tin cans, first consider material safety and product compatibility

The first step in choosing a custom printed tin can is to ensure the material meets your product needs, especially when selling food, cosmetics, or other items that come into contact with the skin or are ingested. Not all tinplate is created equal:

Food-grade tinplate: If your custom printed tin can is intended for snacks (cookies, nuts), tea, or spices, it must be made with food-safe tinplate and an FDA-compliant liner. A common mistake is using non-food-grade cans to package edible products, which can lead to contamination and regulatory fines.

Corrosion Resistance: For products containing moisture, choose tins with a protective coating, such as epoxy phenolic resin, to prevent rust. We once helped a skincare brand redesign its custom-printed tins, resolving a problem where its uncoated tins rusted within three months.

Ignoring these steps can not only compromise product quality but also undermine consumer trust. Custom printed tins should protect your product first, and aesthetics second.

Choose a printing technique that balances durability and design

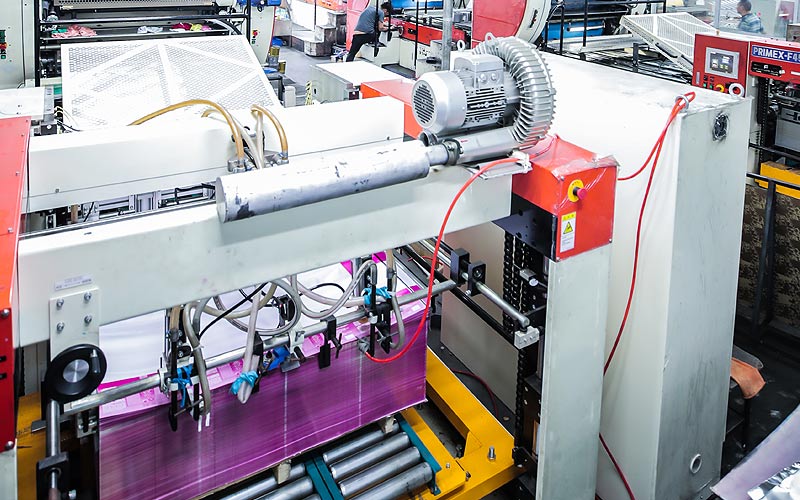

The printing process on custom printed tins is fundamental to their “customization,” but the wrong technique can cause logo fading, image damage, and even ink transfer to the product. There are two primary printing methods for custom-printed tins, each with its own advantages and disadvantages:

Offset printing: Ideal for bold, vibrant images and large production runs (over 6,000 pieces). Offset printing uses high-quality inks that resist scratching and fading even with daily handling. It’s the best choice for brands with complex logos or full packaging designs.

Digital printing: Better suited for products that require frequent design updates. Digital printing is faster and more cost-effective for short runs, but the inks are not as durable as those used in offset printing and may fade with prolonged exposure to direct sunlight.

Also, be sure to ask your supplier to perform a “wear test”: rub a sample can with a dry cloth or expose it to a slightly damp environment to ensure the print remains intact. Proper printing techniques ensure your custom printed cans maintain their professional appearance from shelf to use.

Match the size and shape to your product

Even the most beautiful custom tin cans cannot truly deliver on their primary purpose if they are too large or too small. Some brands often overlook the impact size and shape have on the consumer experience and ultimately, the cost. First, measure the product and allow 10-15% extra space for ease of use. For example, a 4-ounce bag of coffee will need a 6-ounce custom printed tin to fit comfortably, with room for the lid. Furthermore, shipping costs can increase when using oddly shaped or oversized tins. When choosing a shape, consider retail display. Square or rectangular custom printed tins fit standard shelves better than irregular shapes, while small tins suit checkout counter displays. Therefore, you should tailor the size and shape of custom tins to three key factors: your product, your budget, and your retail strategy.

Understanding the Minimum Order Quantity and Lead Time for Custom Printed Tin cans

One of the most common frustrations brands encounter with custom tins is unexpected delays or the need to exceed their MOQ budget. Most custom tin suppliers require a minimum order quantity of 6,000 pieces, which depends on the complexity of the printing. Generally, the production lead time for custom printed tins is around 4-8 weeks. However, the process requires additional time for design approval, sample testing, and shipping. We recommend starting production two months before product launch to avoid delays. Of course, if your demand is stable, you can inquire about volume discounts. It is best to communicate with your supplier about the minimum order quantity and lead time to avoid costly last-minute arrangements.

Leverage post-sale utility as a brand loyalty tool

High-quality custom printed tin cans retain their value even after the product is used; in some cases, users can reuse them. For example, customers can repurpose a tea brand’s tin as a jewelry box or a snack brand’s tin to store office supplies. Add clever details like a “Reuse!” label or internal compartments to encourage consumers to do so. Highlight the tin’s recyclability or reusability in the design. A chocolate brand designed custom printed tins to hold holiday decorations after consumers finished the chocolates, and we collaborated with them on the project. These tins became a seasonal staple, and the brand reported a 40% increase in repeat purchases during the holiday season.

Make tins more tailored to product needs and goals

Choosing custom printed tin cans is more than just picking a beautiful design; it is crucial to align your packaging with the product’s safety needs, budget, retail strategy, and the brand’s long-term goals. By following these five tips—prioritizing material safety, choosing the right printing technology, adjusting sizing for logistics, understanding minimum order quantities, and designing for reusability—you will avoid common mistakes and create tin cans that protect your product, attract customers, and build loyalty.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin