How do Tsing’s custom printed tins meet common packaging customization needs?

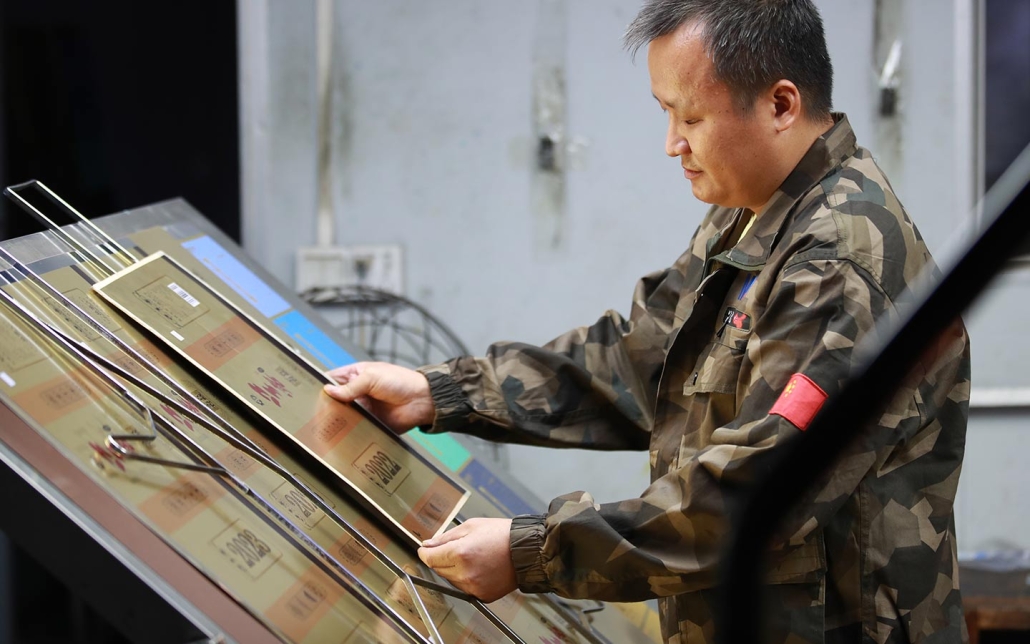

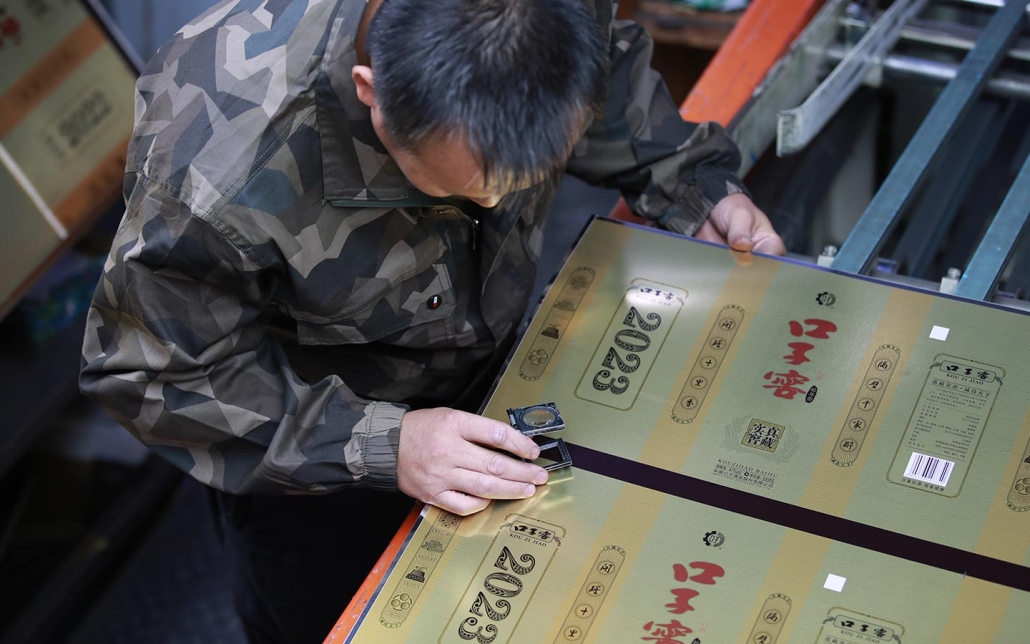

We combine premium materials with high-quality printing techniques to create a carefully designed tin that solves common packaging customization issues while enhancing the unboxing experience by incorporating vibrant colors, complex graphics, and unique textures. Our experienced team utilizes different printing techniques to ensure that every detail is clear and in line with the brand’s vision, enhancing the product’s market appeal. Packaging needs vary greatly across industries, from cosmetics and food to electronics and luxury goods. Customers can get tailored solutions that meet their specific operational requirements and compliance standards with custom-printed tins.

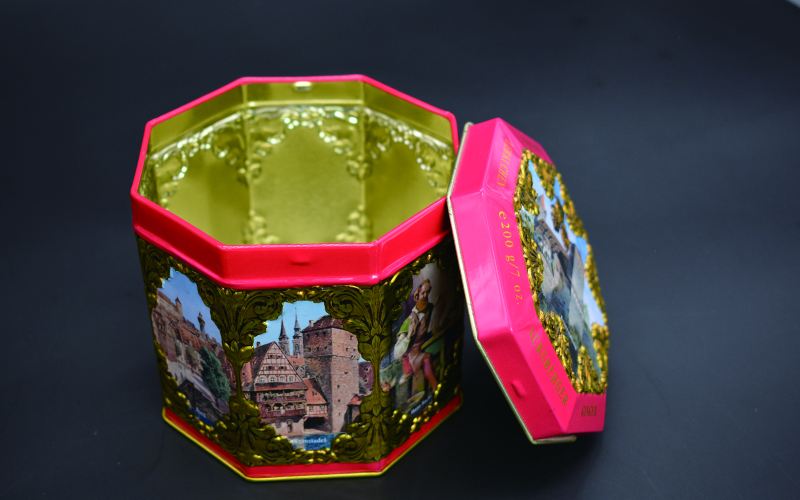

Custom Printed Tins Tailored to Unique Brand Story

Many businesses that create PAA need packaging that protects the product while enhancing the brand image. Custom printed tins provide a unique opportunity for brands to stand out in a saturated market. Packaging directly reflects the brand’s personality, and our advanced digital printing technology, along with other techniques, develops custom printed tins that accurately and vividly reproduce complex designs. This ensures that every detail, from eye-catching logos to subtle textures, is accurately rendered, creating a strong visual impact.

Throughout the design process, we understand each client’s brand’s values, target demographics and specific market trends. This allows us to tailor the design elements of a custom printed tin to reflect the brand’s essence. The final product not only stands out visually but also communicates the brand’s message in a clear and engaging way.

Meeting the need for product protection

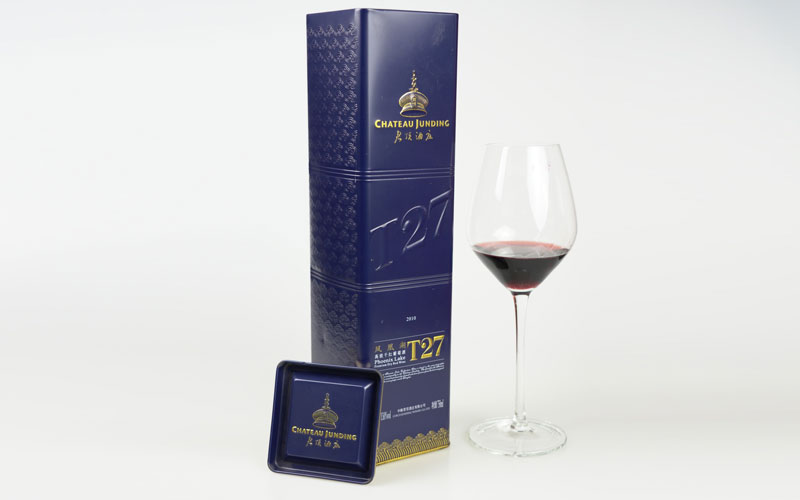

Improper packaging often damages fragile items during shipping, resulting in costly returns and a damaged brand reputation. In response, Tsing’s engineering team designs custom printed tins with precisely calculated structural integrity – thicker tinplate for heavy items, reinforced seams for fragile items, and airtight seals for perishables. Our vibration testing ensures that the design can withstand the rigors of logistics while customizable interior padding options (foam lining, velvet lining or food-safe film) provide product-specific cushioning. Compared to paperboard, our cans are rust-resistant and provide superior moisture protection, especially for international shipments across climate zones. This protection directly means reduced losses and increased customer satisfaction for brands shipping delicate cosmetics, electronic components or premium foods.

Adapting to Changing Market Trends

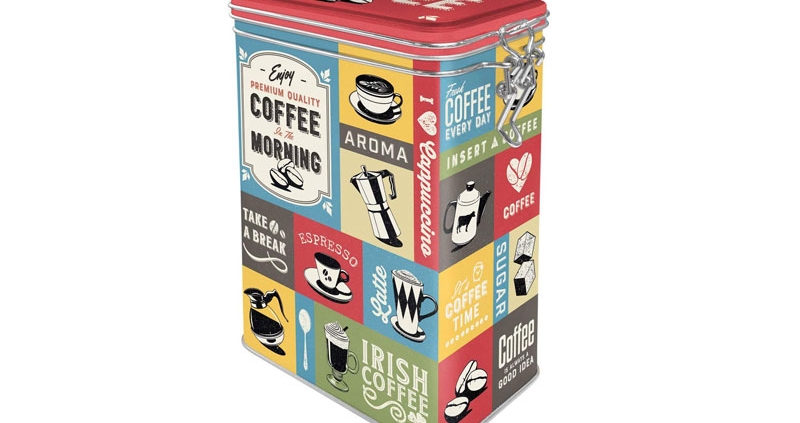

Static packaging can quickly become obsolete in a fast-moving consumer market, leaving brands with outdated inventory. Tsing’s modular design approach allows custom printed tins to be updated cost-effectively through interchangeable components. The base structure can receive a new printed sleeve for annual updates, while embossed elements maintain brand continuity. Our design team monitors emerging trends to advise clients on updates that resonate with their target demographics. During the pandemic, we pioneered a hygienic “touchless” can design with a flip-top opening, demonstrating how we can help brands quickly adapt packaging to changing consumer behavior without a complete redesign.

Custom Printed Tins Meet Sustainability Needs

Environmentally conscious consumers are increasingly rejecting single-use packaging, and Tsing’s custom printed tins offer a reusable solution with 100% recyclable tinplate and food-safe coating materials. We can help clients incorporate sustainability messaging directly into the design with eco-certified badges and clever “reuse me” graphics to encourage secondary use. Our manufacturing process utilizes water-based inks, allowing brands to accurately market their reduced carbon footprint. Our tins offer superior lifecycle value compared to plastic alternatives – market research shows that 68% of consumers keep decorated tins for storage rather than immediately discarding them, significantly increasing brand awareness in households.

Why does customization deliver unparalleled value?

Tsing’s custom-printed tin solutions address modern brands’ core packaging pain points – from sustainability pressures to the need for memorable unboxing moments. Our consultative approach begins with understanding your market challenges and then designing a tin solution that addresses them while amplifying brand equity. Unlike off-the-shelf metal tins, they make every element customizable: metal thickness, closure mechanism, interior finish and decoration techniques, from vintage-style lithography to futuristic holographic foil. Whether you need a holiday-themed tin as a boutique chocolate maker or seek sustainable luxury as a global cosmetics brand, we design our metal tin solutions to meet your needs.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin