How to choose custom tin cans for luxury chocolates and Cookies?

For premium chocolate or cookie brands, a balance must be struck between barrier performance, appearance, ergonomics, manufacturability, and cost. The correct custom tin cans preserves aroma and texture, prevents dents during shipping, supports eye-catching printing or embossing, and simplifies packaging and retail display. We approach this problem from two practical perspectives. First, product quality: chocolate is sensitive to oxygen, moisture, and light; biscuits require pressure protection and moisture resistance. Second, to convey a sense of luxury, your tin must convey high-end quality in a retail environment.

Material and Construction Selection for Custom Tin Cans

Material choice impacts the hardness, printability, weight, recycling characteristics, and cost of custom tin can. Currently, there are two primary materials: tinplate and aluminum. Each offers its advantages for premium chocolate and cookie tins.

Tinplate is the industry standard for many high-end tins and is the primary material used by Tsing. It offers dimensional stability, excellent print surface fidelity, and excels in deep drawing or complex shapes. Tinplate’s hardness also provides excellent dent resistance, making it particularly useful for delicate box-style cookie tins or multi-layer chocolate tins. Modern interior lacquers and BPA-free formulations ensure food safety; for export, manufacturers must comply with FDA 21 CFR, EU food contact regulations, and India’s FSSAI standards. Aluminum is lightweight and naturally corrosion-resistant, making it an ideal choice for applications where lightweighting and corrosion resistance are crucial, such as coastal distribution corridors in Canada or the UK. Aluminum’s soft surface may limit specific embossing depths, but anodizing offers superior aesthetics and long-term durability.

Specific construction types include one-piece, deep-drawn cans with separate lids, two-piece cans, and hinged-lid cookie tins. For layered chocolate packaging that may undergo heat treatment, two-piece cans with high seam integrity are recommended. For high-speed filling of biscuits, standard cylindrical cans with a diameter of 202-206 mm or rectangular tins with a rolled seam are typically used.

Internal Coatings, Food Safety, and Barrier Requirements for Chocolate and Cookies

Choosing the right inner coating and barrier layer for your custom tin cans is key to flavor protection and shelf life. The inner coating prevents metal from reacting with the food and controls aroma transfer. For high-end chocolate and biscuit tins, coatings primarily consider three aspects: chemical inertness, migration restrictions, and regulatory compliance.

Typical linings include epoxy phenolic resins, polyester-based lacquers, and specialized food-grade polymers, all of which provide excellent oxygen barriers. For fatty or acidic fillings (such as chocolates with added citrus or nut oils), Tsing uses coatings proven to resist fat migration and dissolution. If your product requires longer-lasting flavor preservation, consider using an aluminum foil induction seal or a polymer liner under the lid for additional barrier properties.

Custom tin can suppliers also provide migration test certificates to ensure compliance with the US Food and Drug Administration (FDA) and EU Directive 10/2011, or equivalent regulations currently in force in Canada and the UK. You must provide accelerated shelf-life testing data demonstrating volatile organic compound (VOC) migration, along with sensory panel testing results after 3–12 months at actual storage temperatures. For high-fat chocolates, combining oxygen scavengers or nitrogen flushing with tight-fitting lids and liners can extend shelf life. For cookie tins, consider using desiccants or liners to reduce moisture intrusion during frequent box openings.

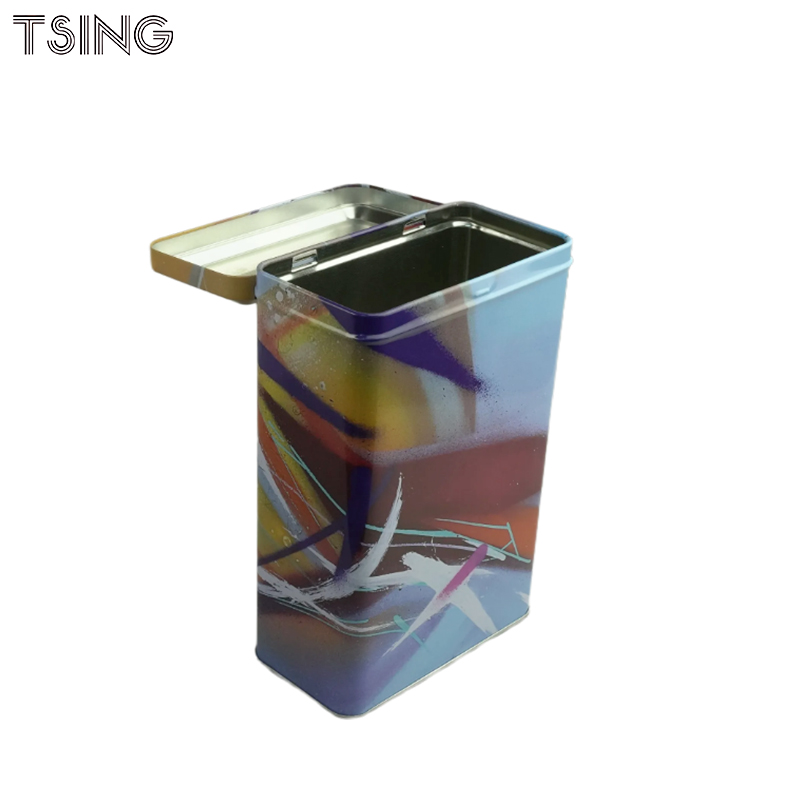

Designing Custom Tin Shapes to Embody Luxury

The size, shape, and internal structure of a custom tin determine the product’s visual impact, heft, and protective qualities. For premium chocolate assortments and artisan cookies, the packaging design within the tin significantly impacts the perceived value of the product.

Primarily, size is determined by portion size (e.g., a 12-piece chocolate box, an 18-piece cookie assortment). Size selection influences shelf presentation—tray-style displays suit wider, shallower tins better. Taller tins highlight the product’s richness. Standard rectangular or round jars simplify production. However, custom shapes such as hexagons or hearts can significantly enhance brand differentiation but increase tooling costs. For chocolate tins, custom thermoformed trays or die-cut cardboard dividers secure individual components and prevent movement. For cookie tins, corrugated paper or foam trays prevent breakage during stacking. Design inserts for quick placement on automatic filling machines, coordinating tongue dimensions and indexing capabilities to match your filling line.

Tin lid and seal types typically include friction-fit, hinged, or twist-off caps. Hinged-lid cookie tins offer a premium unboxing experience and are popular in the gift market. Hinged designs increase mold complexity and minimum order quantities. For high-value chocolate jars, consider using induction seals or inner laminates to retain aroma during opening.

Enhancing a sophisticated appearance through printing, embossing, and special treatments

High-end chocolate and confectionery rely on tactile and visual elements. Embossed logos, metallic foils, soft-touch lacquers, and selected varnishes all highlight their premium positioning. For custom tins used as chocolate and cookie jars, choose a finish that balances brand image and durability under retail lighting and handling conditions.

In terms of printing technology, offset printing on tinplate offers high-resolution, smooth color reproduction, making it ideal for complex color gradients. Digital printing (UV curing) reduces lead times and enables cost-effective customization. Furthermore, tactile embossing enhances visual value, particularly for logos or graphics. Embossing depth should be coordinated with the lid geometry; shallow embossing (0.4-0.8 mm) avoids thinning the metal. If specialized finishes are desired, consider metallic foil (hot stamping), soft-touch coatings, and textured lacquers.

Luxury Packaging for Premium Chocolates and Biscuits

Choosing the right custom tin can for luxury chocolates and biscuits begins with product protection needs: selecting a material and inner coating that prevents aroma migration and verifying this through migration and accelerated aging testing. Next, determine the geometry and inner lining to protect fragile products and optimize the appearance. Finally, specify a decorative technique that aligns with your luxury positioning, while also confirming printing tolerances and abrasion resistance.

Common Questions When Choosing Custom Tin Cans for Chocolates and Biscuits

Q1. Which material best preserves the aroma of premium chocolate: tinplate or aluminum?

A1: Both materials are acceptable, but tinplate is often used for premium chocolate tins due to its structural rigidity and excellent printability. Tinplate is coated internally with a proven food-grade lacquer. Aluminum is lighter and more corrosion-resistant; your choice should be based on your distribution channels and aesthetic needs, and verified through migration testing.

Q2. Which inner coating should I choose for high-fat chocolate?

A2: Choose a coating that has been tested for grease resistance—either an epoxy phenolic or a polymer liner specifically designed to prevent grease migration.

Q3. Will the embossed finish be durable in retail circulation?

A3: Yes, as long as the embossing depth and metal thickness are appropriate (medium embossing depth is typically 0.4-0.8 mm) and the finish includes a protective varnish.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin