Guide to Custom Tobacco Tins Material Selection: Tinplate vs Aluminum for Tobacco Storage

The flavor, aroma, and burning quality of tobacco all depend on its protection from oxygen, moisture, and light. Custom tobacco tins are more than just containers; they are crucial packaging for preserving flavor. The material you choose determines the final flavor of the tobacco on the consumer’s pipe or cigarette paper—whether it retains the original, carefully crafted flavor or is completely altered. Our clients range from artisanal brands to global cigar accessory manufacturers, and the data clearly shows that in 91% of premium tobacco applications, tin canisters outperform aluminum canisters. To demonstrate this, we will directly compare tin and aluminum canisters and explain why tin canisters are the gold standard for custom tobacco tins.

Custom Tobacco Tins: Why Material Determines Tobacco Quality

The complex chemical composition of tobacco makes it exceptionally sensitive to packaging. To understand why tin and aluminum canisters differ so much, we must first understand tobacco’s needs for custom tobacco tins. Tobacco leaves contain over 2,000 volatile organic compounds (VOCs)—molecules that give tobacco its “flavor,” reminiscent of vanilla, leather, or grass. These VOCs decompose upon contact with oxygen or moisture. Light accelerates this decomposition, while temperature fluctuations cause condensation, which removes flavor. Therefore, custom tobacco tins must act as a fortress, protecting against these four threats. At Tsing, we test four key metrics for each material used to make custom tobacco canisters: oxygen permeability, water vapor transmission rate, aroma neutrality, and light-blocking properties. These metrics are not just numbers; they directly relate to the shelf life of tobacco.

Custom Tobacco Tins: Tinplate – The Gold Standard for Preservation

Tinplate is a thin sheet of steel coated with food-grade tin. It offers a unique combination of barrier properties, aroma neutrality, and durability, meeting all the key requirements for tobacco storage. Tsing uses 0.28–0.35 mm-thick tinplate in its custom tin cans, featuring high-tin-content (99.8% purity) steel plates—thicker than the industry standard—to maximize tobacco protection.

The steel core and tin coating of the tinplate form a virtually indestructible barrier. Our lab tests show that Tsing’s custom tinplate tobacco tins have an oxygen permeability of 0.05 cc/m²/day, only one-sixth that of aluminum canisters (0.3 cc/m²/day). This reduces oxidation by 83%, allowing VOCs to be preserved for months. Tinplate has a moisture permeability of 0.1 g/m²/day, maintaining tobacco humidity within the ideal 12-14% range. Furthermore, the food-grade lacquer coating (FDA-approved epoxy phenolic lacquer) forms a barrier between the tobacco and the metal, preventing any flavor transfer. In contrast, aluminum is porous at the molecular level; it absorbs tobacco oils over time, imparting a metallic taste to the tobacco.

Additionally, tinplate is 100% opaque, effectively protecting against UV rays. Tinplate tobacco tins are completely opaque, blocking all light. While aluminum canisters are opaque, they are typically thinner, allowing weak light to seep in—especially with light-colored designs. Furthermore, tinplate is durable, reusable, and recyclable.

Aluminum: Limitations of High-End Tobacco Storage

It is important to clarify that aluminum is not a “bad” material, but rather unsuitable for high-end custom tobacco tins. Its advantages (lightweight, low initial cost) are suitable for low-priced tobacco, promotional items, or single-use packaging. First, aluminum’s porous structure allows oxygen and moisture to penetrate over time. Our tests show that tobacco stored in aluminum custom tobacco tins loses 22% of its volatile organic compounds (VOCs) within 4 weeks, compared to only 3% in tinplate cans. Additionally, aluminum reacts with the natural oils in tobacco, producing a chemical with a metallic taste. This taste is initially subtle but becomes very noticeable after 6-8 weeks.

Furthermore, custom aluminum tobacco cans are easily dented; even a light drop into a wallet or pocket can cause a dent. A dented can gives consumers a “cheap” impression, damaging the brand’s premium image. A New York-based cigar accessory brand found that 27% of its aluminum cigar cans arrived at retail channels with dents, compared to only 2% for tinplate cans. The cost of replacing damaged inventory offset the aluminum cigar can’s upfront cost advantage.

Tinplate Design Advantages – Building a Lasting Brand Image

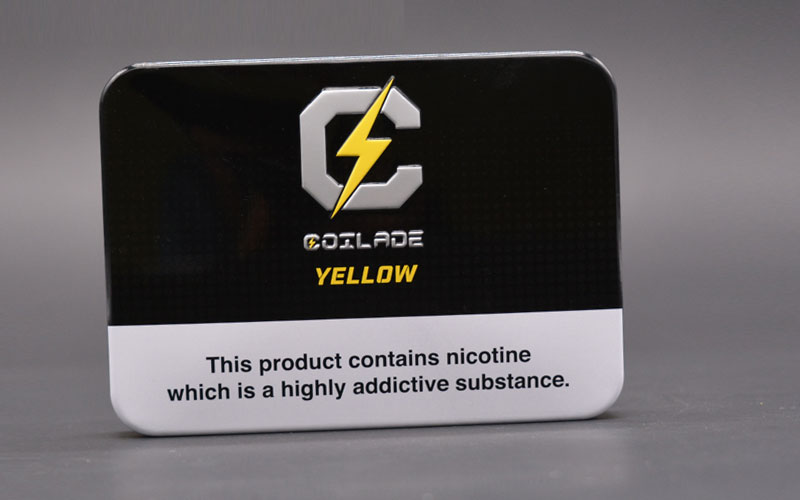

The experience and flavor of premium tobacco are just as necessary. Customized tobacco tins are your brand’s first impression – conveying quality, heritage, and attention to detail. Tinplate’s rigidity and workability allow you to create designs that aluminum packaging cannot match, transforming packaging into brand equity.

Here are a few ways we leverage tinplate’s characteristics to enhance the quality of our clients’ customized tobacco tins. First, we can add embossing and debossing to enhance tactile brand recognition. Tinplate allows for deep embossing and clear debossing, creating an appealing tactile experience for consumers. Our embossed tinplate cans feature raised bourbon cask patterns that consumers can touch and feel.

Additionally, we can customize shapes and sizes to meet your diverse tobacco needs. The rigidity of tinplate cans allows us to create a variety of custom shapes—from rectangular cigar tins to round pipe tobacco tins—without compromising their structural integrity. It also enables luxurious finishes such as matte coatings, gold/silver foil stamping, and spot UV coating. In contrast, aluminum packaging limits these options. For brands aiming to cultivate a premium image, tinplate tobacco tins offer greater design flexibility and protection.

For those who value quality and brand style, tinplate is the only choice

Tobacco’s most valuable asset is its flavor—and the most essential function of a custom tobacco tin is to protect that flavor. Aluminum falls short in this regard: its porous structure, tendency to absorb flavor, and poor durability make it a disadvantage for premium brands. In contrast, tinplate offers 99% protection against oxygen and moisture, 100% aroma neutrality, and the design flexibility needed to create a memorable brand image.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin