How to choose the right candle tins for your candle business?

If you just start your candle business and don’t know what kind of candle tin you will choose for your start-up business, this article will help.

Currently there are kinds of different shapes and structure candle tins in the market, round, square, rectangle, egg, heart and many other different candle tins. Whatever shape you choose, there is one very important thing you need to confirm, that is, the tin container will not leak when store candle wax.

In the market, the candle tins can be divided into two kinds of structures, one is seamless tin and the other is the seam tin.

Let’s talk about the seamless candle tins first, the seamless candle tins won’t leak when storing candles. But it has disadvantages, as it uses body and base one-body design, there is a stretch process in production, so it will limit the artwork design. We suggest to use just one color or irregular artwork design, as regular shape (such as squares, circles, triangles, words) will be out of shape after the stretching process.

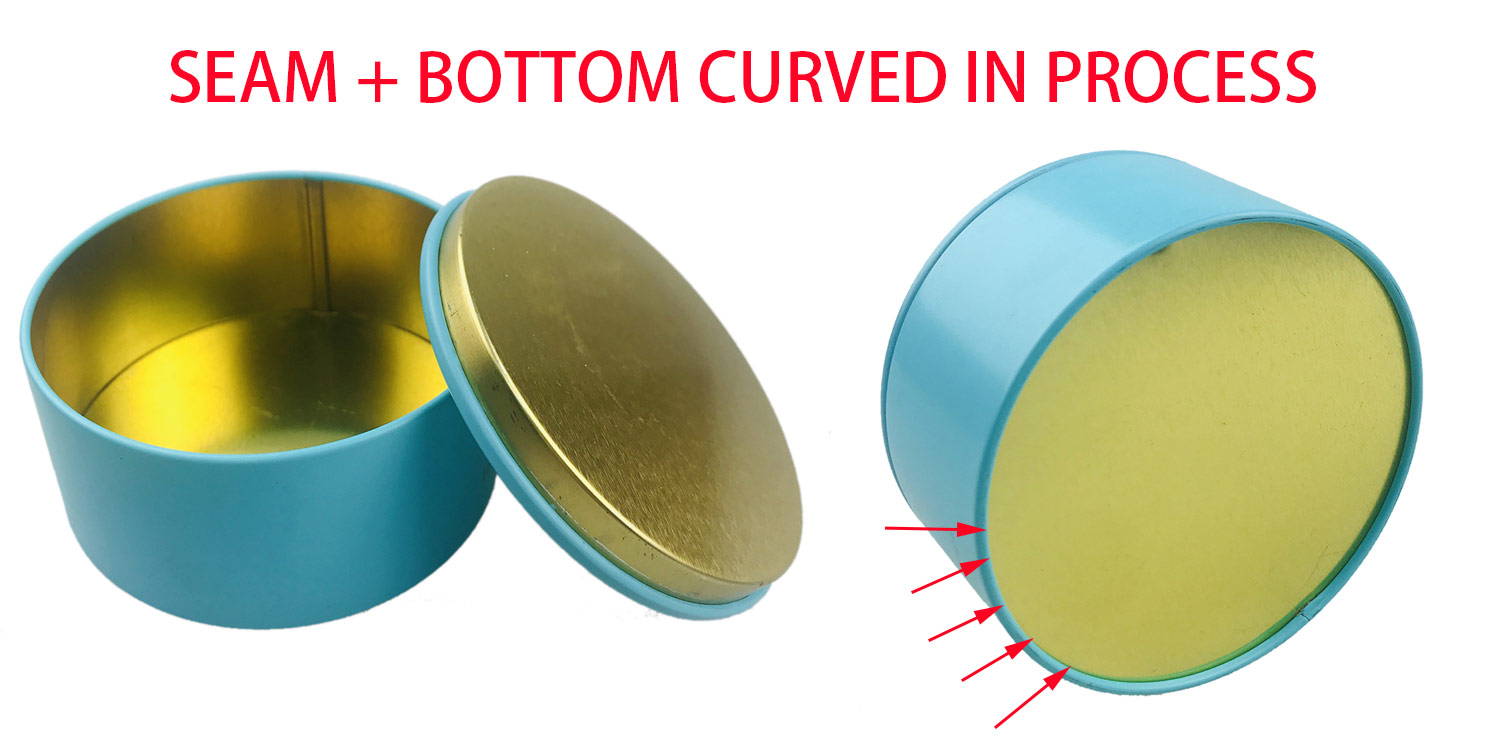

Then it’s to the seam candle tins. For the seam candle tins, let’s divide it into the body seam area and the bottom seam area.

The body seam can have the welding process and the normal seam connection process. If you choose the welding process tin, then we are also sure that it won’t leak if used to store candle wax. But it has a disadvantage, the body welding area can’t print artwork design, and it will only be the silver, which is the color of tinplate.

As to normal seam connection process for body, then the bottom seam area can be curved in process and the curved out process. Let’s talk about the body normal seam connection process + bottom curved out process first, for this kind of candle tins, we will use glue at the connection area to confirm it won’t leak when store candle wax. We can confirm with this operation, the tin won’t leak. And this kind of tin won’t limit the printing artwork design.

Then it’s the normal seam connection process + bottom curved in process, for this kind of tin, even if we use glue at the connection area, we can’t confirm it won’t leak when used to store candle wax. So we don’t suggest to use this kind of tin to store candle wax.

If you still have any questions in customizing your candle tins after reading this article, please feel free to contact us here.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin