Why do tea and coffee brands prefer to use double-lid tins to keep their products fresh?

Tea and coffee, among other beverage categories, have extremely high requirements for freshness. Even slight exposure to oxygen, light, or humidity can damage sensitive components such as polyphenols in tea or aromatic oils in coffee. In high-end beverage packaging, these subtle changes translate into significant sensory differences. Therefore, packaging decisions must meet technical performance requirements, not just aesthetics. Consequently, major tea and coffee manufacturers are increasingly choosing double-lid tins to ensure optimal product quality from the bottling line to the end consumer.

How do double-lid tins maintain freshness better than standard packaging?

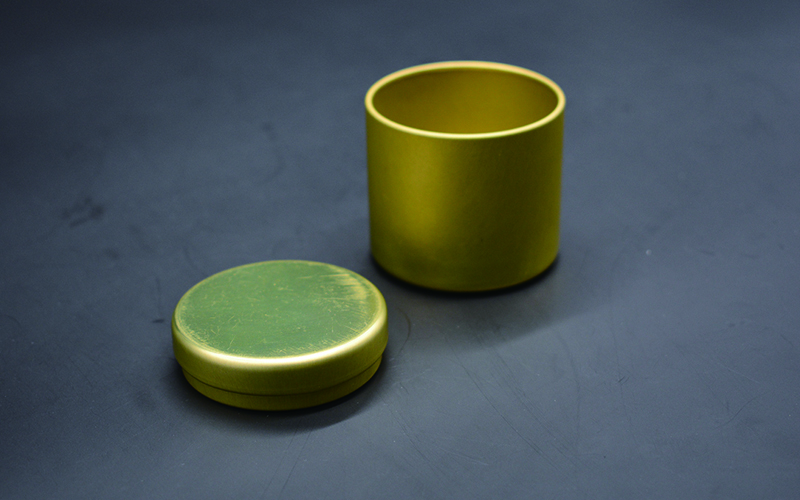

Tea and roasted coffee beans contain volatile organic compounds (VOCs), which give them their unique aromas. Upon contact with oxygen, these compounds begin to oxidize, gradually diminishing the flavor’s complexity. Double-lid tins solve this problem through a double-barrier structure. The outer lid isolates the product from the external environment, while the inner lid forms a second seal, locking aroma molecules inside the can. This double-layer structure reduces the exchange of internal air during repeated use. Unlike single-lid systems, which allow air to circulate directly whenever the container is opened, a double-lid tin creates a controlled buffer zone. Therefore, the oxidation process is slower, thereby improving the product’s long-term stability.

Humidity Control and Oxygen Barrier Performance

Moisture is particularly harmful to tea, as it accelerates spoilage and can lead to clumping or mold growth. For coffee, oxygen exposure is a major threat, leading to rancidity and flavour loss. Double-lid cans reduce both risks simultaneously. The inner lid significantly reduces airflow after opening, thus limiting moisture penetration in humid climates and oxygen entry in dry environments.

Furthermore, high-quality double-lid tins are manufactured with tight dimensional tolerances, ensuring uniform lid compression. This high precision minimizes micro-gaps that could affect barrier performance. Compared with flexible packaging bags or standard tin cans, double-lid tins provide a more stable internal environment, helping maintain the product’s texture, aroma intensity, and overall sensory quality.

Structural Integrity and Sealing Stability of Double-Lid Tins

Preservation depends not only on materials; structural stability is equally crucial. Double-lid tins are typically made of robust tinplate with reinforced edges, and the connection between the lid and the can body is carefully designed. This structure resists deformation during stacking, transportation, and storage. Even under mechanical stress, the seal integrity remains intact. Furthermore, the performance of double-sealed cans does not significantly degrade after repeated opening and closing cycles. The inner lid maintains a reliable frictional fit, ensuring a stable compression force. This durability also reduces the risk of seal failure.

Why do tea and coffee brands strategically choose double-sealed tins?

Packaging influences consumer perception. When consumers open a double-sealed tin and see an inner lid, this experience reinforces the impression that the product has been carefully preserved. This “secondary revelation” conveys a psychological signal of premium quality. In addition, consumers often associate double-sealed canned products with high-end products. For brands, this perception enhances consumer trust and encourages repeat purchases. Over time, packaging design becomes part of the brand image.

Resealability and Convenience for Everyday Use

Unlike vacuum-sealed bags, whose barrier effect diminishes after the first opening, double-sealed tins are designed for repeated use. Even in daily use, the inner lid maintains a partial seal on the contents. This feature is especially important for coffee lovers who open the can every morning or tea enthusiasts who brew tea multiple times a week. Because the inner lid reduces direct exposure to air, flavor degradation is significantly slowed. Consumers can enjoy the product’s consistent aroma throughout its entire lifespan. At the same time, the robust structure prevents accidental crushing or tearing, a common problem with flexible packaging. Therefore, double-sealed cans are more suitable for practical use than ideal storage conditions.

Providing Better Sealing

If your product’s value depends on its aroma, as with most speciality teas and many coffee products, a double-sealed tin can is undoubtedly the most suitable packaging choice. The double-sealed design effectively reduces oxygen contact, stabilizes internal humidity, and retains the volatile aromatic compounds that determine product quality. For loose tea and freshly roasted coffee, this extra layer of protection directly ensures the flavor integrity of every cup from production through the final consumer experience.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin