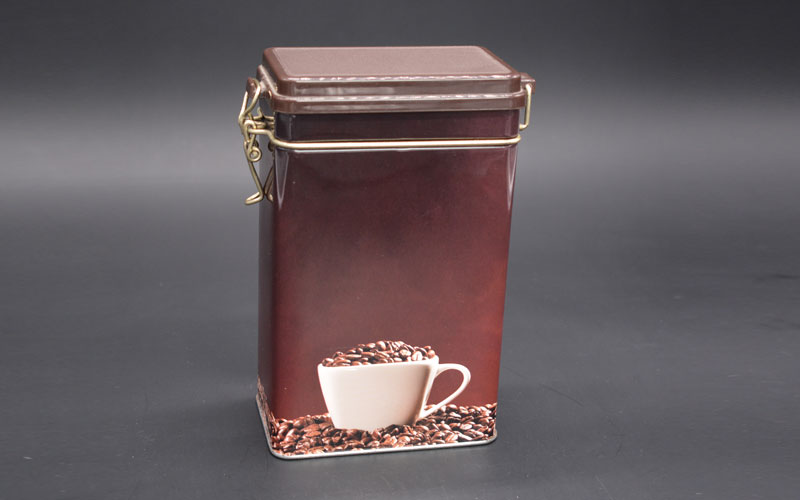

What designs of bulk candle tins can solve the sealing needs of solid wax melts?

Production data shows that more than 95% of wax melt formulations lose fragrance or absorb moisture when the packaging seal fails. So we address this issue by combining precision-fit lids, integrated gasket solutions, and engineered lip profiles in each bulk candle tins. First, we use a food-grade silicone liner on the inside of the lid to create a tight-fitting seal that resists wax vapor and external moisture. Then, we apply a crimped edge to the edge of the custom candle tin, which interlocks with the lid flange to prevent capillary leaks that can occur due to thermal expansion or contraction caused by temperature cycling. Finally, we add a snap-on lid with an undercut feature that snaps securely into place, ensuring the stringent sealing requirements of solid wax melts.

Precision Bulk Candle Tins Lid Geometry

The key to the sealing performance of bulk candle tins lies in the geometry and manufacturing tolerances of the lid. We machine the tin lid to have an interference fit of 0.05 mm on the tin body, and we control the lid diameter within ±0.03 mm throughout the production process. At the same time, I specified a conical taper in the lid design to compress slightly when closed, creating uniform radial pressure across the entire sealing surface. Engineers developed a dual-stage edge design where the inner ring seals against the tin shoulder while the outer ring aligns perfectly with the lid flange. The manufacturing process rolls each ring in separate stamping operations to guarantee dimensional consistency.

This concentric seal structure not only blocks the vapor path but also resists deformation under repeated thermal cycling and mechanical treatment. By optimizing these dimensional tolerances and geometric features, the candle tin can maintain the integrity of the wax and lock in the fragrance.

Integrating Gaskets and Liners in Bulk Candle Tins

To further enhance the sealing of bulk candle tins, Tsing integrates customized gaskets and liner materials directly into the lid assembly. In addition to the main silicone liner, we also offer EPDM foam liners for scented essential oils and textured wax blends, providing compression sealing and chemical resistance. Typically, we choose 1 mm EPDM, which maintains its elasticity and sealing force at temperatures up to 80°C, ensuring it will not permanently deform and ensuring long-term sealing integrity during transportation and display.

At the same time, the liner is bonded to the underside of the lid using a food-safe, high-temperature adhesive to ensure that it will not delaminate over hundreds of open/close cycles. Additionally, we customize the liner hardness to match the specific wax melt viscosity, thereby preventing wax migration into the gasket area. This ensures sealing performance and extends the shelf life of the solid wax melt.

Carefully designed lip and bead profiles

The lip profile of Tsing bulk candle tins is also essential for sealing performance under pressure. Our 1.5mm deep rolled flange at the tin mouth provides a solid compression surface for the lid. Therefore, the seal can remain intact even if the tin deforms slightly due to thermal expansion or stacking loads. In addition, I designed a double-stepped flange that creates two independent sealing lines: one radial and one axial. This dramatically reduces the risk of leakage along the thermal expansion joint or handling shock.

In addition, the flange cross-section is carefully designed to minimize springback by optimizing metal work hardening during the molding process, ensuring that the lid remains consistently meshed over multiple cycles. By creating these precise lip and flange profiles, Tsing’s custom tins meet the sealing performance needs of solid wax melts.

Snap-on and thread-on closure options

There are multiple sealing mechanisms in the production of bulk candle tins to accommodate different candle production processes and end-use scenarios. Our snap-lock lids feature precision undercuts, providing an audible click that gives the operator immediate confirmation of proper engagement. For high-pressure or tamper-evident applications, we also offer fine-pitch threaded lids with a calibrated 2 Nm torque for a repeatable, leak-proof seal and clear torque markings. Both types of seals feature the same integrated gasket and bead system, ensuring uniform barrier performance and aesthetic consistency. These versatile sealing designs enable Tsing’s bulk candle tins to accommodate various production processes, providing an excellent user experience.

Material selection and coatings to ensure seal integrity

The substrate and coating of bulk candle tin are critical to their sealing performance and overall durability. In addition to 0.30mm D+E grade tinplate, we use a 7-micron epoxy liner to stop corrosion and a 5-micron food-grade polymer coating on the underside of the lid, which enhances adhesion to the silicone liner and resists attack by essential oils. We verify corrosion resistance through a 500-hour salt spray test, with no rust or adhesion loss observed at the sealing interface. A low-profile exterior lacquer, available in either matte or gloss finishes, is also used to minimize the thermal expansion mismatch between the lid and the tin, thereby reducing stress on the seal. With high-quality tinplate, liner, and exterior coating, Tsing’s candle tins maintain an airtight seal even under repeated heating and cooling cycles.

Meeting the sealing needs of solid wax melts.

Tsing’s bulk candle tins address the sealing needs of solid wax melts by incorporating a fitted lid, an integrated gasket liner, a carefully designed lip profile, a flexible closure mechanism, and rigorous quality assurance testing into the design. Customizing candle tins maintains product integrity, enhances consumer experience, reduces returns, and supports users to enter the high-end market.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin