Solving the problem of mismatched tobacco packaging sizes: Custom cigarette tin case services

When your new product is about to launch, but off-the-shelf packaging boxes aren’t suitable—cigarettes rattling around, corners exposed, or the box looking bulky and crude—these small flaws can silently damage your brand image and increase return costs. We’ve seen too many examples of this among our clients. Therefore, “solving the problem of mismatched cigarette packaging sizes” is a core service for us. Custom cigarette tin cases can eliminate size mismatches, protect your product, and enhance the brand experience. We will also show you how to choose the right cigarette tin case and how custom cigarette tins can achieve stable packaging quality practically and economically.

Determining the Basic Elements of Cigarette Tin Case Dimensions

Precise dimensions are the foundation of any successful cigarette tin case. First, accurately measure your product: length, width, height, and any irregular external features, such as filter caps, recessed mouthpieces, or protective sleeves. When measuring, consider the manufacturing tolerances of the cigarettes themselves, as well as any inner lining or foil. For cigarettes with soft packaging or sliding lids, measure both the compressed and fully extended states to determine the worst-case clearance.

Next, determine the performance margin. A tight fit prevents movement and protects the product; a slightly looser fit may be easier for the end user to insert and remove. Industry practice typically uses a clearance of 0.5–1.5 mm per side for hard cigarettes or pre-filled tins. Still, the specific clearance will vary depending on the product’s fragility and user preference. If you plan to accommodate multiple packaging types in a single tin design, clearly define the acceptable minimum and maximum dimensions, and we will reserve space for internal dividers or foam padding. Additionally, when working with Tsing or other cigarette tin manufacturers, provide clear dimension drawings or samples. This helps improve mold accuracy; physical samples allow for rapid prototyping and size verification.

Materials and Surface Treatments for Custom Cigarette Tin Case

The choice of material directly affects appearance, protective performance, weight, and cost. Tinplate remains the industry standard for cigarette tin cases due to its good formability, recyclability, and printability. For high-end product lines, we can use thicker tinplate to increase weight, or aluminum to enhance corrosion resistance and provide a premium feel.

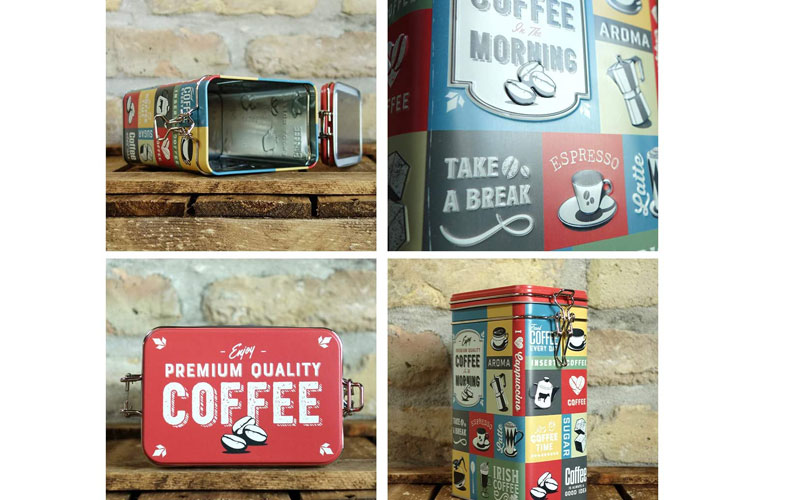

Custom surface finishing transforms functionality into a brand experience. Offset printing allows for full-color images and photographic detail. Embossing and debossing add tactile differences, enhancing the product’s perceived value. Additionally, special finishing options—such as soft-touch coatings, matte varnish, gloss varnish, spot UV, hot stamping/silver stamping, or flocking—create unique shelf appeal. When choosing decorative patterns for custom cigarette case tins, consider printing registration accuracy: multi-part tins require precise alignment during decoration to ensure the pattern aligns perfectly when closed.

Determining Structural Design, Lid Type, Closure Method, and Protective Features

Structural design balances size and functionality. First, determine the lid style: hinged, removable, sliding, or drawer-style. Hinged lids are popular for their everyday convenience and can be designed with a robust, shallow seam to ensure a tight closure. Removable lids typically have a cleaner appearance and are easier to manufacture, while sliding or drawer-style lids offer both novelty and internal structural stability.

The seal integrity of the cigarette tin case impacts its protective performance. A tight-fitting friction seal or snap-fit inner lip prevents accidental opening during transport. If tamper-evident features are required, designs such as pull tabs, tamper-evident bands, or shrink wrap can be incorporated. For high-end or collectible cigarette tin cases, magnetic closures or precisely engineered nesting lids provide a satisfying user experience. Internal protective components are also crucial. Soft foam padding, protective film, or inner sleeves reduce product movement and minimize wear on the printed surface. If needed, we can add internal ribs or shoulders to secure the product in a precise position, ensuring consistent presentation upon opening.

Decoration and Printing for Visual Impact

Decoration can transform an ordinary cigarette tin case into a brand ambassador. The most common process for high-quality cigarette tins is offset printing the design onto the tinplate before forming. This process allows for vibrant colors, crisp text, and intricate images. Please ensure design files are high-resolution and provide color references.

When planning brand design, we consider the physical geometry of the cigarette tin case, including the wrap-around design, embossed areas, and the alignment of the lid and base, as these factors affect the placement of the artwork. If you plan to use embossing, we will create separate artwork layers for the raised areas and consider using spot varnishing or hot stamping to highlight these details. Furthermore, for limited-edition or high-end products, combining hot stamping, UV spot varnishing, and embossing techniques can create a premium feel while ensuring reproducible, scalable production of custom cigarette case tins.

Quality Control, Testing, and Compliance

We implement incoming material inspection to check tin plating thickness and coating uniformity, in-process inspection, and final inspection for all types of tin production. Statistical process control (SPC) is used for critical dimensions and decorative tolerances to detect deviations early.

Regulatory compliance is equally important. Depending on the target market, Tsing’s cigarette packaging must comply with labeling regulations, health warnings, child-resistant designs, and specific material restrictions. For example, some regions restrict the sale of flavored tobacco or require standardized packaging elements; your custom cigarette tins must comply with mandatory labeling requirements and not violate any laws.

Delivering Consistent Cigarette Packaging

Our custom cigarette tin service effectively addresses size inconsistencies by combining precise dimensions, material and surface finish selections, clever structural design, accurate decoration, and strict production controls. If you are currently experiencing packaging size inconsistencies, start by recording your existing packaging dimensions and analyzing your target market and regulatory requirements. With this information, we can provide you with an optimized design solution.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin