Solving the problem of limited customization options: A tin box manufacturer supporting full-range design

Many consumers say that “unique packaging” makes them more likely to buy a product. Still, many small and medium-sized enterprises struggle to find tin box manufacturers that can provide the customization services they need. Due to the ubiquitous use of generic tin boxes, each brand loses a portion of its customers on average. Tsing, as a tin box manufacturer with years of experience, offers comprehensive customization capabilities, providing end-to-end design solutions including size, shape, and surface treatment, at a cost far exceeding your expectations.

The Hidden Costs of Limited Custom Design Options

First, decreased brand awareness. Whether you’re selling delicious cookies or handmade candles, the tin can is your first impression. Generic silver or black tin boxes are buried on the shelf, making it impossible for customers to spot your brand. Second, missing out on market segments. Third, higher waste and costs. Generic metal cans rarely fit your product perfectly. Fourth, stifled product innovation. When tin can manufacturers only offer three sizes and two shapes, you’re forced to design products around the tin can, not the other way around. What’s the root of the problem? Most tin box manufacturers prioritize mass production over flexibility.

A Comprehensive Tin Box Manufacturer – From Size to Finish

As a tin box manufacturer specializing in comprehensive design, Tsing offers far more customization options than any other manufacturer. We don’t just offer “more colors,” we let you tailor every detail of your tin box to your brand, product, and target audience. Our process revolves around three core pillars: form, function, and appearance.

1. Form: Size and Shape – Fit Your Product

We offer 10 standard sizes, as well as an unlimited number of custom sizes accurate to 0.1 ounces. In terms of shape, Tsing offers classic shapes: round, square, and rectangular. Unique shapes: hexagonal, oval, heart, star, and even brand-specific shapes. Stackable and nestable: custom sizes for easy storage.

2. Function: Functionality to Meet Your Specific Needs

Customization is more than just about appearance – it’s about making your tin boxes more convenient for you and your customers. As a tin box manufacturer that listens to brands’ pain points, we offer customized features for different industries: Food & Beverage: sealing silicone gaskets, easy-tear lids, and moisture-proof linings. Beauty & Skincare: Magnetic closure, removable inner tray, UV-resistant coating. Gifts & Crafts: Hinged lid, ribbon loop, custom lining.

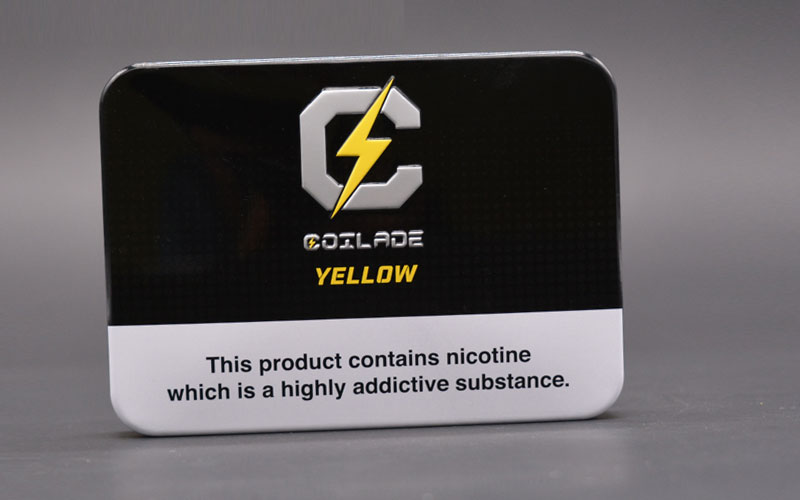

3. Brand Appeal: Surface Finishes & Brand Identity

We offer over 15 surface finishes and 8 brand identity technologies designed to make your products stand out on the shelf and give customers a premium feel: Surface Finishes: Matte, Gloss, Metallic, Textured, and Recycled. Brand Identity: Full-color CMYK printing, embossing, debossing, hot stamping (gold/silver), and QR codes.

Material & Safety Customization to Meet Industry Needs

1. Food-Grade Tinplate: Safe, Fresh, and Compliant

For food products ranging from cookies and popcorn to spices and honey, we use 0.23mm thick food-grade tinplate (compliant with FDA, USDA, and EU 10/2011 standards). Key customization options include:

Food-grade liner: BPA-free epoxy resin or polyester liner prevents the tin can from reacting with acidic foods.

Oxygen barrier layer: For perishable foods like dried meat or dried fruit, a thin aluminum layer blocks 99.9% of oxygen, extending shelf life by 30%.

Child-safe lid: Suitable for brands selling nuts or candy in areas with strict food safety regulations.

2. Eco-friendly tin boxes: Meeting consumer demand for sustainability

73% of US consumers say they are willing to pay a higher price for products with sustainable packaging. To address sustainability needs, we offer:

Recycled tinplate: Made from 95% recycled steel.

Plastic-free design: No plastic windows, liners, or seals; paper inserts or tinplate windows are used instead.

Soy-based ink: Non-toxic, biodegradable ink, replacing petroleum-based inks.

3. Durable Tin Cans: Suitable for Shipping, Gift Giving, and Reuse

Some brands require tin cans that can withstand rough handling or frequent use. We offer custom thicknesses (0.20mm–0.30mm thick tinplate) and reinforced edges to enhance durability.

A Tin Box Manufacturer Providing Functional and Creative Structural Designs

Many tin box manufacturers rely on pre-made molds to shorten production time, limiting structural choices to standard shapes such as round, square, and rectangular. However, at Tsing, structural design should be as flexible as your brand, perfectly blending functionality and creativity to create tin boxes that stand out on the shelf and complement your products. Whether you need stackable tin boxes for easy retail display, foldable tin boxes for easy transport, or tin boxes with unique opening mechanisms, our in-house engineering team can bring them to life.

Functional-structural design is essential in specific industries. For example, pet food brands often need airtight, easy-to-open tin boxes to maintain pet food freshness and allow pet owners to open them with one hand. Meanwhile, we also design tin cans for the tech industry that double as charging-cable storage, featuring custom-designed dividers and foam linings to protect delicate electronic devices effectively. These structural innovations not only enhance the practicality of tin cans but also transform them into value-added products that customers keep long-term, thereby continuing to expand brand influence after use.

Leveraging Visual Design to Build Brand Image

Visual design is the window to a brand’s personality, but for brands with limited customization options, this is often the most challenging aspect. Many tin can manufacturers only offer basic printing techniques, such as offset printing with limited color choices, or charge extra for custom designs, gradients, or special surface treatments. At Tsing, we consider visual design an integral part of the customization process, offering a full range of printing and surface treatment options to ensure your tin cans perfectly match your brand aesthetic.

Our printing capabilities encompass offset, screen, digital, and hot stamping—each suited to different design needs. Additionally, we offer a range of specialty processes to enhance visual appeal, including embossing, debossing, spot UV coating, and matte lamination. These techniques add texture and depth to tin cans, making them more eye-catching and memorable.

Your Custom Tin Can Partner

Tsing is committed to providing comprehensive design services, always putting your brand needs first. From material selection to structural design, from visual aesthetics to manufacturing, we control every step to ensure your custom tin cans are not only functional but also a true extension of your brand. What sets us apart is not only our technical expertise but also our collaborative philosophy. We take the time to understand your goals, answer your questions, and tailor our services to meet your unique packaging needs.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin