What are the best metal specifications for a batch of durable cigarette tins case?

When we worked with a tobacco brand, they reported that their initial order of 5,000 cigarette cases developed dents during shipping because the supplier used 0.20mm-thick metal. We restructured their order to optimize the specifications, and they haven’t had any issues in the past 3 years. The key to ensuring the durability of the cigarette tins case in large-volume orders lies in selecting the right metal, thickness, coating, and manufacturing specifications.

Cigarette Tins Case Metal Material Selection—Tinplate vs. Aluminum

The base metal material for a durable cigarette tin case is currently one of two main choices in the industry: tinplate and aluminum. For bulk orders where durability is paramount, tinplate is the gold standard, but aluminum is also suitable for specific applications. Here’s a breakdown:

Tinplate: The most durable cigarette tin case choice. Made with a steel core and tin-plated, it offers excellent impact resistance. Tinplate can withstand drops and stacking without denting, which is crucial for bulk shipping. Additionally, it provides excellent rust resistance, and the tinplate coating acts as a moisture barrier even in humid warehouses. Meanwhile, this material is easier to mold into standard cigarette tin case sizes, with tight seams. 90% of Tsing’s bulk orders use food-grade tinplate (compliant with 21 CFR Part 175 of the FDA and EU Regulation 10/2011), which is safe for direct contact with cigarettes.

Aluminum: Lighter than tinplate, but less impact-resistant. Best suited for high-end lightweight cigarette cases, it also offers some rust resistance, but is more prone to dents than tinplate.

A national tobacco brand switched its bulk cigarette tin cases from aluminum to tinplate: “We had 8% of our aluminum cans dented during shipping. With tinplate, the dent rate is less than 1%—the slight increase in weight is worthwhile for durability.”

Cigarette Tins Case Thickness Specifications—0.23–0.28 mm

Metal thickness is a key parameter that determines the durability of cigarette tin cases—too thin and they’re easily dented; too thick and they’re too expensive. Based on Sing’s years of manufacturing experience, the ideal thickness range for tinplate cigarette boxes is 0.23–0.28 mm:

0.23 mm: The minimum thickness to guarantee bulk durability. Suitable for standard 20-pack cigarette boxes, it is less prone to dents during normal transport and stacking. It is the best size to balance cost and durability.

0.25 mm: The most popular specification for bulk orders. Offers additional impact resistance without a significant increase in cost.

0.28 mm: Suitable for heavy-duty needs (e.g., international shipping, long-term storage). Recommended for brands sold in humid areas or shipped by sea.

It is important to avoid thicknesses below 0.20 mm, as these cigarette boxes will dent if stacked to a height of more than 10.

Coatings and Linings for Rust Prevention and Freshness Preservation

Even the best metals require coatings to maximize durability and maintain cigarette quality. For bulk cigarette boxes, two coatings are essential:

Lining: Food-grade epoxy coating: In direct contact with cigarettes, therefore must be non-toxic and moisture-proof. Tsing uses BPA-free epoxy resin (FDA- and EU-certified) that prevents metal from contacting tobacco. It prevents moisture from seeping into the can, extending the cigarette’s shelf life by 6-12 months. It also resists the corrosive effects of tobacco oils.

Outer Coating: Matte/gloss protective layers protect the can from scratches, fingerprints, and rust. Some common options include a matte finish, which is highly fingerprint-resistant and enhances a premium look. Gloss finishes enhance brand image and are easy to wipe clean.

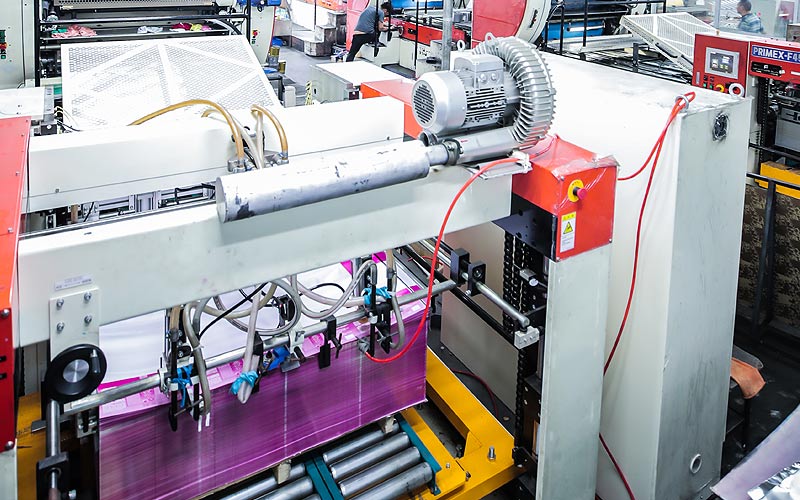

Both coatings are applied by electrostatic spraying, a crucial factor for batch consistency. A tobacco brand specializing in menthol cigarettes states, “Tsing’s internal epoxy coating keeps our cigarettes fresh for 8 months.”

Seams, edges, and lid fit ensure batch durability.

Durability depends not only on the metal used but also on the cigarette case’s manufacturing process. For large orders, here are the manufacturing specifications Tsing uses to ensure consistency and strength:

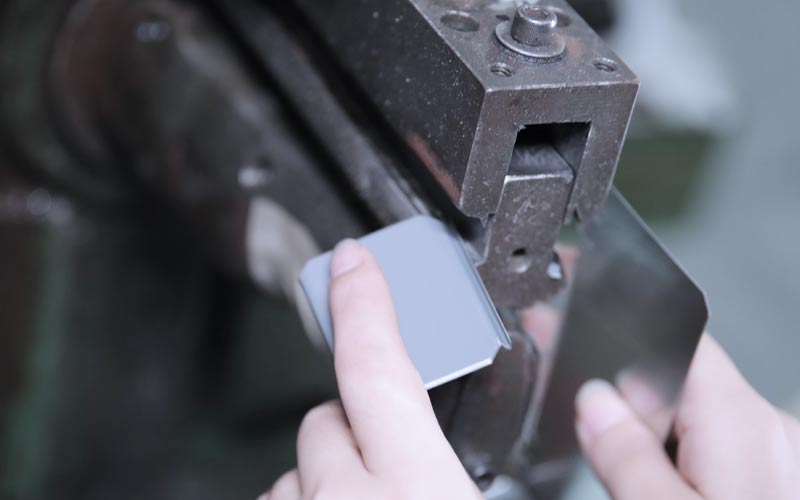

Double-Seam Construction: The lid and body feature double-rolled seams to prevent leakage and separation during transport. Tsing’s double-seam overlap is 0.3 mm.

Reinforced Edges: Top and bottom edges feature a rolled edge design to avoid sharp edges and enhance structural rigidity. Unreinforced edges are prone to bending during bulk stacking.

Tight-Fitting Lids: Lids that are too loose are prone to leakage; lids that are too tight are difficult to open. Tsing uses CNC molds to ensure the lid is aligned with the body.

Bulk Order Considerations, Consistency, and Quality Control

For high-volume production (6,000 pieces and above), consistency is just as important as durability. Even a single defective can out of 100 cans results in losses. Tsing’s bulk cigarettes can include metal specifications, include stringent quality control (QC) measures:

Material Batch Testing: Before production, each roll of metal undergoes thickness testing (tolerance ±0.01 mm) and tin coating weight testing (minimum 0.5 μm).

Process Inspection: Every 100 cans undergo dent resistance testing, drop testing, seam strength testing, tensile testing, and coating adhesion checks.

Final Batch Audit: 5% of the total order undergoes a consistency check to ensure no variations in thickness, coating, or fit.

This quality control reduces the batch defect rate to below 0.5%, ensuring seamless transitions for your tin cans during bulk shipping and retail distribution.

Optimal Metal Specifications

For bulk orders of durable cigarette tin cans, the optimal metal specifications are:

Material: Tinplate (0.23–0.28 mm) for maximum durability.

Coating: BPA-free epoxy liner (moisture-resistant/durable) and matte/gloss exterior coating (scratch-resistant).

Manufacturing: Double-seam construction, reinforced edges, and a tight lid fit.

With over 20 years of experience in bulk production, Tsing has refined these specifications to strike a balance between durability, cost, and cigarette freshness, ensuring your batches withstand shipping, storage, and retail use. Whether you order 6,000 cans or 600,000 cans, these specifications carry potential risks.

Facebook

Facebook Twitter

Twitter Linkedin

Linkedin